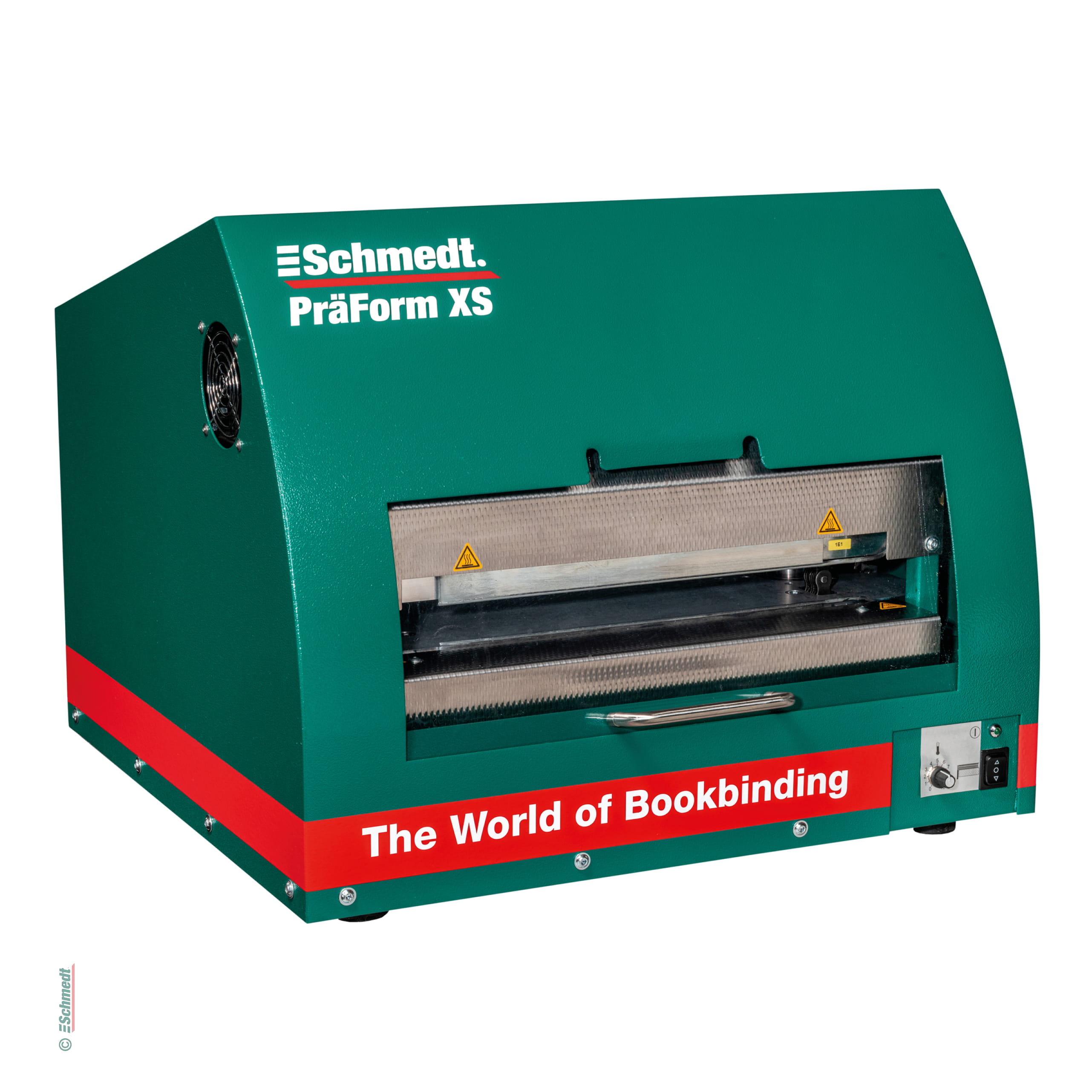

PräForm | Book press

Pressing and joint-setting machine

The PräForm is a book press and joint-setting machine. It is equipped with two light-metal pressing plates of 520 x 450 mm and with heated joint formers. The machine is factory-equipped with rounded (“bull-nose”) joint formers for gentle joint-setting especially for cellophaned and laminated papers as well as other binding materials such as cloth. Optionally, it may also be equipped with pointed or rectangular joint formers. The pressure of the joint formers is adjustable independent of the pressing plates by regulating the air pressure and may therefore be adapted to the binding material used and the joint depth required. The temperature of the joint formers is controlled by touchscreen and is set according to the requirements of glue, binding material and also working speed. A light-line helps to align the book for single books. For serial production, an adjustable back stop helps to speed up alignment. The pressing time may also be adjusted by touchscreen. After this period of time, the press opens automatically and the book can be taken out. Therefore, the working cycle can be adapted precisely to the casing-in speed, i. e. the PräForm is already open when the next book is to be inserted. This speeds up the working process considerably. The press may also be opened manually by push-button any time.

Process

- After casing-in the book is placed on the bottom pressing plate with the joint lying on the joint former. The upper joint former is marked by a light line.

- When single (assorted) books are being produced, the top pressing plate can be lowered onto the book by foot-treadle to align the book with greater accuracy.

- For series production, the machine is equipped with a back stop which is adjusted to the book size. The stop is released by push-button, aligned according to the book width and fixed at the correct position by the push-button. All further books is pushed against the stop only and is aligned properly.

- After activating the pressing process by pressing the push-button "Close press", the pressure of the joint formers is established when the pressing plates are already pressing. This ensures that upper and lower joint are pressed equally. Moreover, temperature, pressing time and pressure of the joint formers can be adapted to the product to obtain perfect results.

- After the preset pressing time, the machine opens automatically (or manually by pressing the push-button "Open press" and the pressed book can be removed. Usually it is then stacked to dry out and does not need any more pressing.

- All settings such as pressing time, pressure, temperature and automatic opening are edited via a touchscreen. External access is possible by built-in LAN port.

- Working speed and operation of the PräForm are matched for use with our PräLeg casing-in machine. Both machines can be operated by one person so that a high output can be achieved. However, the pressing of books cased-in manually is also possible.

| Dimensions | |

| Block height (mm): | 100 - 520 |

|---|---|

| Block thickness (in mm): | 6,5 - 100 |

| Block width (mm): | 120 - 450 |

| Depth (mm): | 810 |

| Height (in mm): | 1470 |

| Weight: | 264 kgs |

| Width (in mm): | 880 |

| Output | |

| Output (pcs/h): | 150 |

| Output level: | Level 2: 101 - 200 pcs/h |

| Format range | |

| Block height (mm): | 100 - 520 |

| Block thickness (in mm): | 6,5 - 100 |

| Block width (mm): | 120 - 450 |

| Connectors | |

| Air pressure supply (bar): | 6 |

| Electric power: | 2000 W |

| Power supply: | 230-240 V / 50-60 Hz |

| Other properties | |

| Category: | Casing-In, Pressing and Joint-setting |

Login

Below you can see questions that other customers have asked about this product. Do you have a question of your own? Then feel free to ask us using the button below. You decide whether your question may be published.

Advantages

The PräForm is based on the 2-way system, which means that two work steps, namely mechanical pressing and pneumatic fold firing, are carried out fully automatically one after the other - another work step is saved. The PräForm can be ideally adjusted to the casing-in machine so that work processes run smoothly. In addition, the PräForm guarantees optimum shaping of the book joints (the fold). Pressing pressure, pressing time and temperature can be adjusted individually, depending on the material. Straight and rounded books can be produced excellently. The whole thing is adjusted via the integrated touch screen, which has intuitive menu navigation. A fold can also be burned into special materials such as textiles, leather and fabrics.

There are no set-up times when working.

The book joints are optimally shaped for a noticeable fold.

All relevant settings can be adjusted via the touch screen.

Pressing pressure, pressing time and temperature can be adjusted for different products.

First the book is mechanically pressed together and then the fold is pneumatically burned in.

The PräForm is optimised for use with the PräLeg casing-in machine.

There are no set-up times when working.

The book joints are optimally shaped for a noticeable fold.

All relevant settings can be adjusted via the touch screen.

Pressing pressure, pressing time and temperature can be adjusted for different products.

First the book is mechanically pressed together and then the fold is pneumatically burned in.

The PräForm is optimised for use with the PräLeg casing-in machine.

The PräForm in combination with the PräLeg

The PräForm is a book press and joint-setting machine for the production of medium-high quantities of hardcover books in varying formats. The PräForm is combined with the PräLeg (casing-in) to produce precisely cased-in books with a beautiful fold and good opening behaviour. A more productive version of the PräForm is the Pro version, with multi-station system and stacker, which enables the pressing of up to eight books simultaneously: