In stock, deliverable at short notice

Available, ready to ship in approx. 2 days

In stock, deliverable at short notice

In stock, deliverable at short notice

Available, delivery time on request

Important factors for gluing machines are the format to be processed, the type of glue used, viscosity control and cleanability.

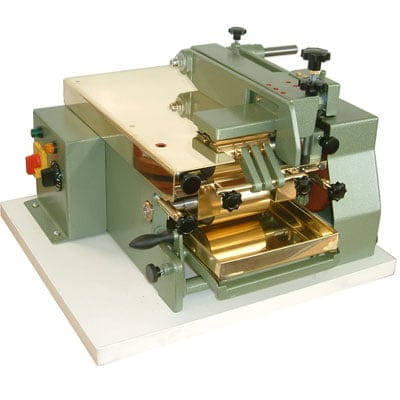

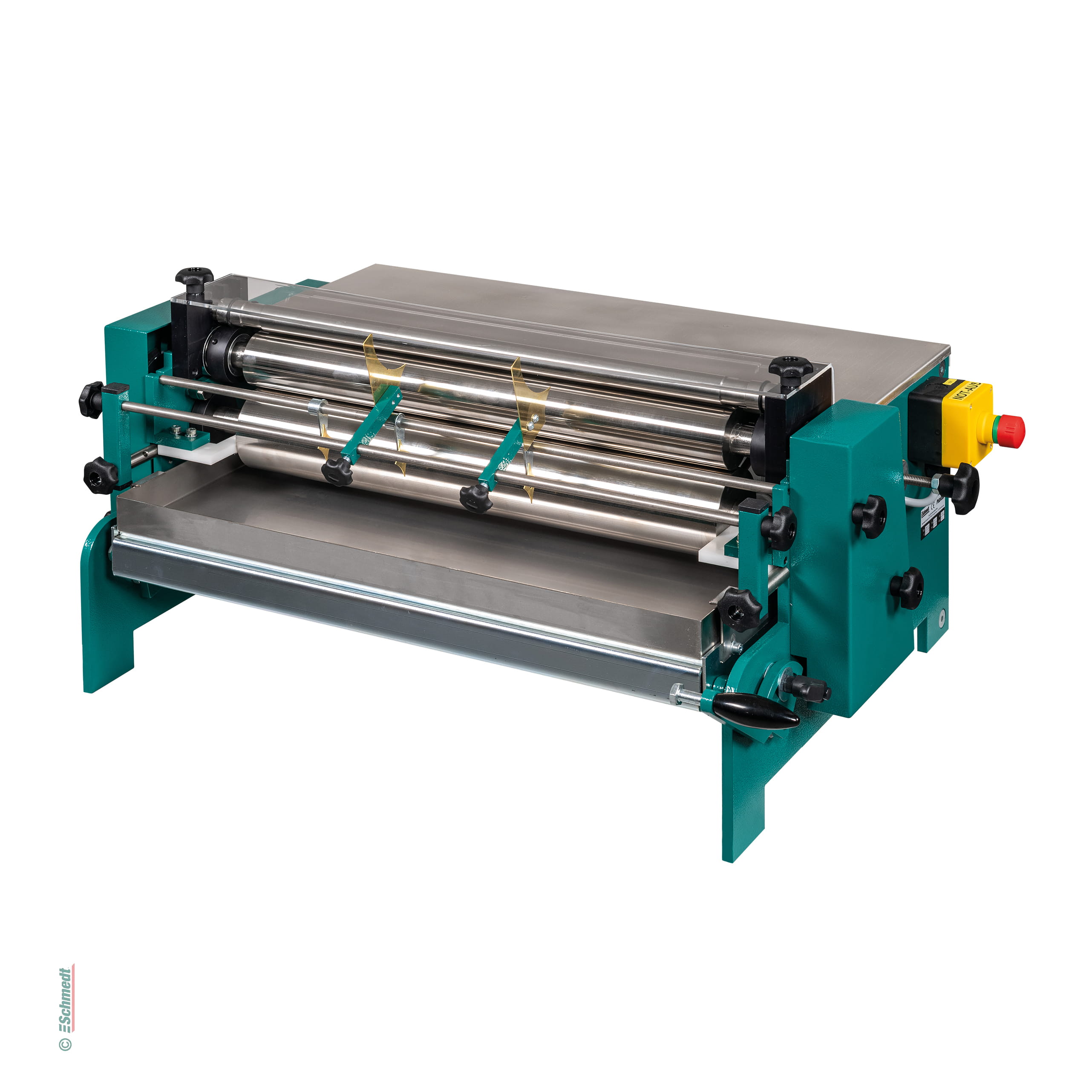

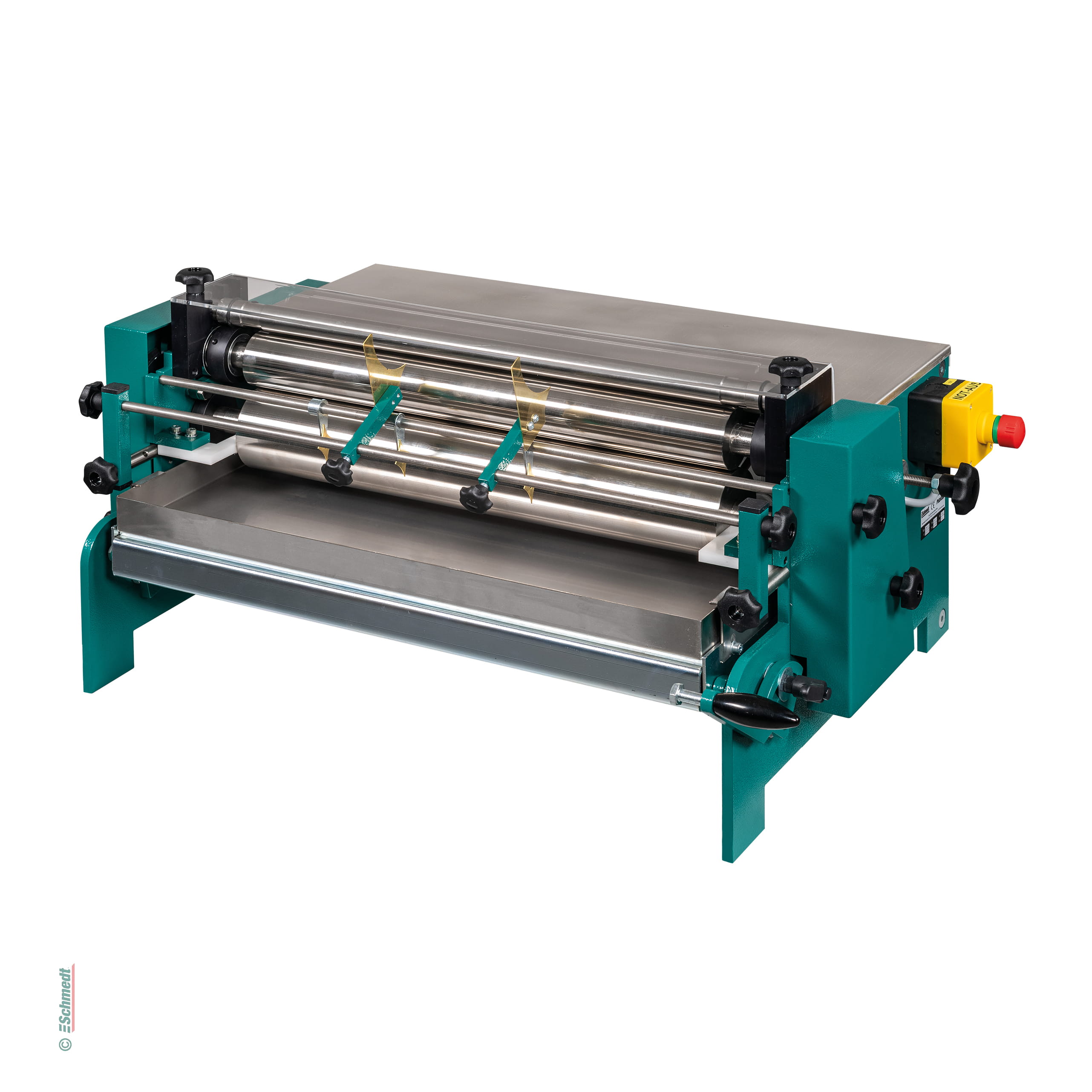

For gluing machines, as a rule, only one side of the utility (usually the width) is decisive for the format that can be processed. In order to be able to process very large formats, we offer different versions of our gluing machines. Our PräziCoat, for example, is available with three roller widths: 400 millimetres, 520 millimetres or 720 millimetres.

The type of glue used is a decisive factor in the purchase of a gluing machine. If only cold glue is used and no changes are expected in the production process or in the materials to be processed, a cold gluing machine can be purchased with peace of mind. However, if you want to have the flexibility to process both cold and hot glue, you should choose a machine that can process both types of glue.

For the processing of hot glue, our PräziCoat can be optionally equipped with an automatic water feed (PräVis). This ensures a constant viscosity - and thus guarantees exact and reproducible results. Our PräziCoat Pro is equipped with an integrated viscosity control, which measures the viscosity of the adhesive during operation and adds water if necessary.

Because we come from a practical background, we place a high value on the simplicity of cleaning in our machines. When using hot glue, the glue basin is lowered and excess glue is brushed off the rollers and then rinsed with water. The machine is then left to cool down. When using cold glue, the basin is simply filled with water and the rotating rollers clean themselves.