Book block production

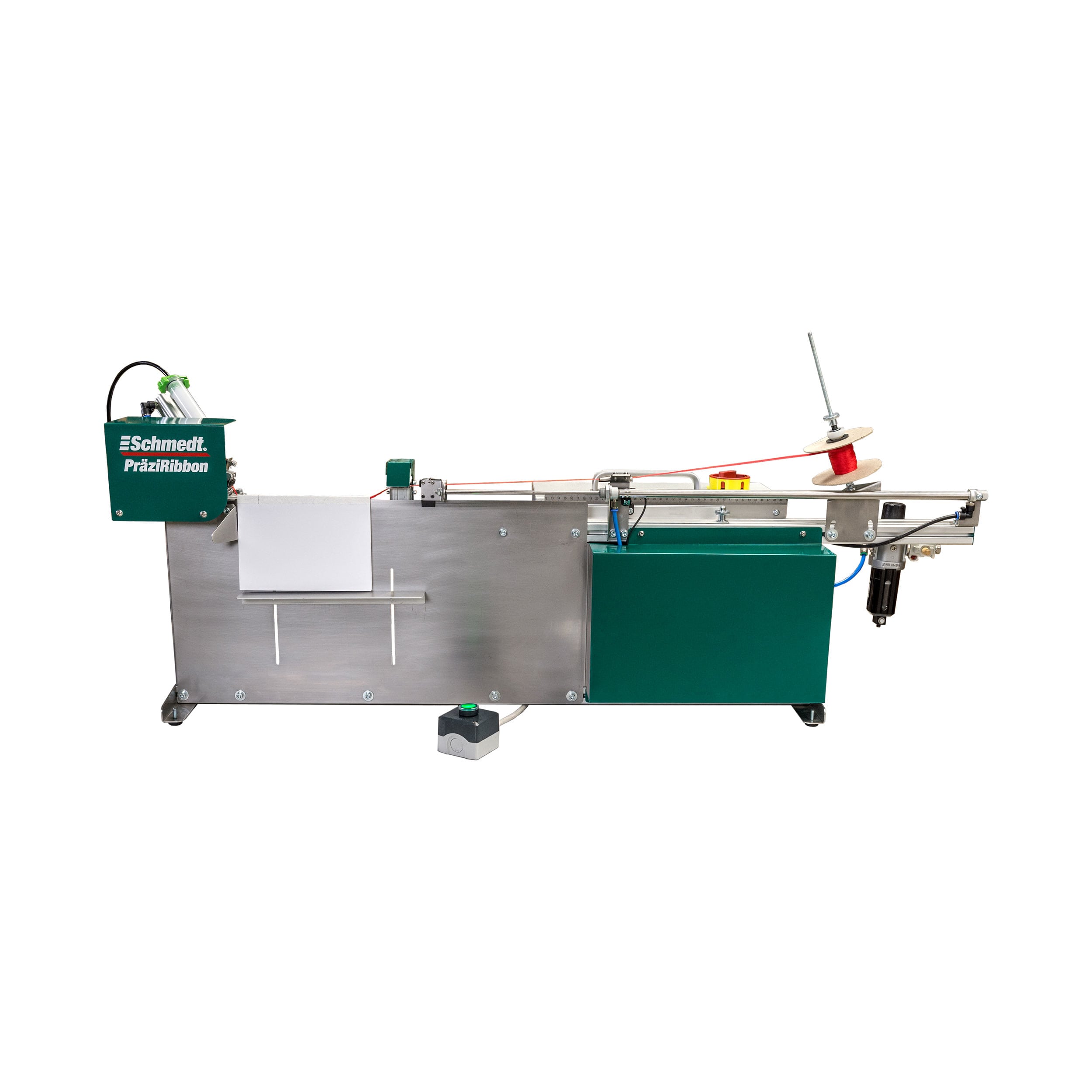

Binding individual pages into a book block by applying glue to the spine is an important process in book production - this is the heart of the book. In addition to our combined endpaper PräziCover, which enables every perfect binder to produce hardcover book blocks, we also offer special solutions for the production of book blocks: the PräColl fan glue binder, the PräziBind layflat binding system and the PräziGard endpaper gluing machine.

All machines for producing book blocks

In stock, deliverable at short notice

In stock, deliverable at short notice

In stock, deliverable at short notice

Available, delivery time on request

Available, delivery time 1-2 weeks

In stock, deliverable at short notice

Available, delivery time on request

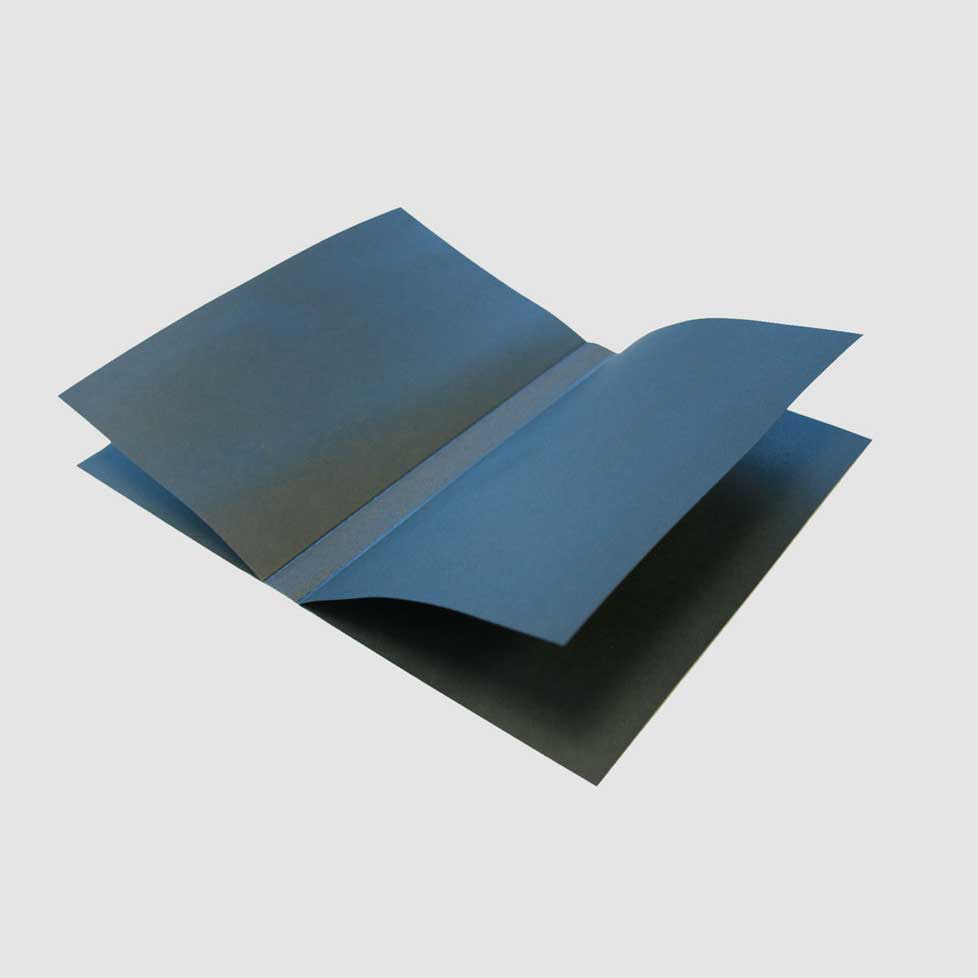

A hardcover book block usually consists of two central components that must be brought together during book block production: the individual pages and the endpaper (also called endsheets). Different types of books (such as photo books or library volumes) have different requirements for the book block. Generally speaking, however, the most important requirements for a book block are that it is durable and opens well. For a photo book, however, the opening behaviour and the possibility to open it completely flat (layflat) is much more important than for a conventional book. The paper also plays a major role in the choice of finishing method. To reflect the diversity of books in production, there are a variety of binding techniques and machines that make the job easier, each with their own advantages and disadvantages.

The most common technique for producing hardcover books is to use an adhesive binder, as is also used for softcover production. To produce a high-quality book block, real endsheets should be used. This can be done, for example, with a perfect binder with a folding and endpaper feeding station, via which a folded endpaper can be fed into the perfect binder. If you don't have a folding station or an attachment feeder station on your perfect binder, you can still produce high-quality books with our combined endsheets PräziCover. Since many producers already own a perfect binder for producing soft covers, they can use PräziCover, even without a large investment.

Other methods are thread stitching and binding types specially developed for hardcover books such as fan glue binding and layflat binding.

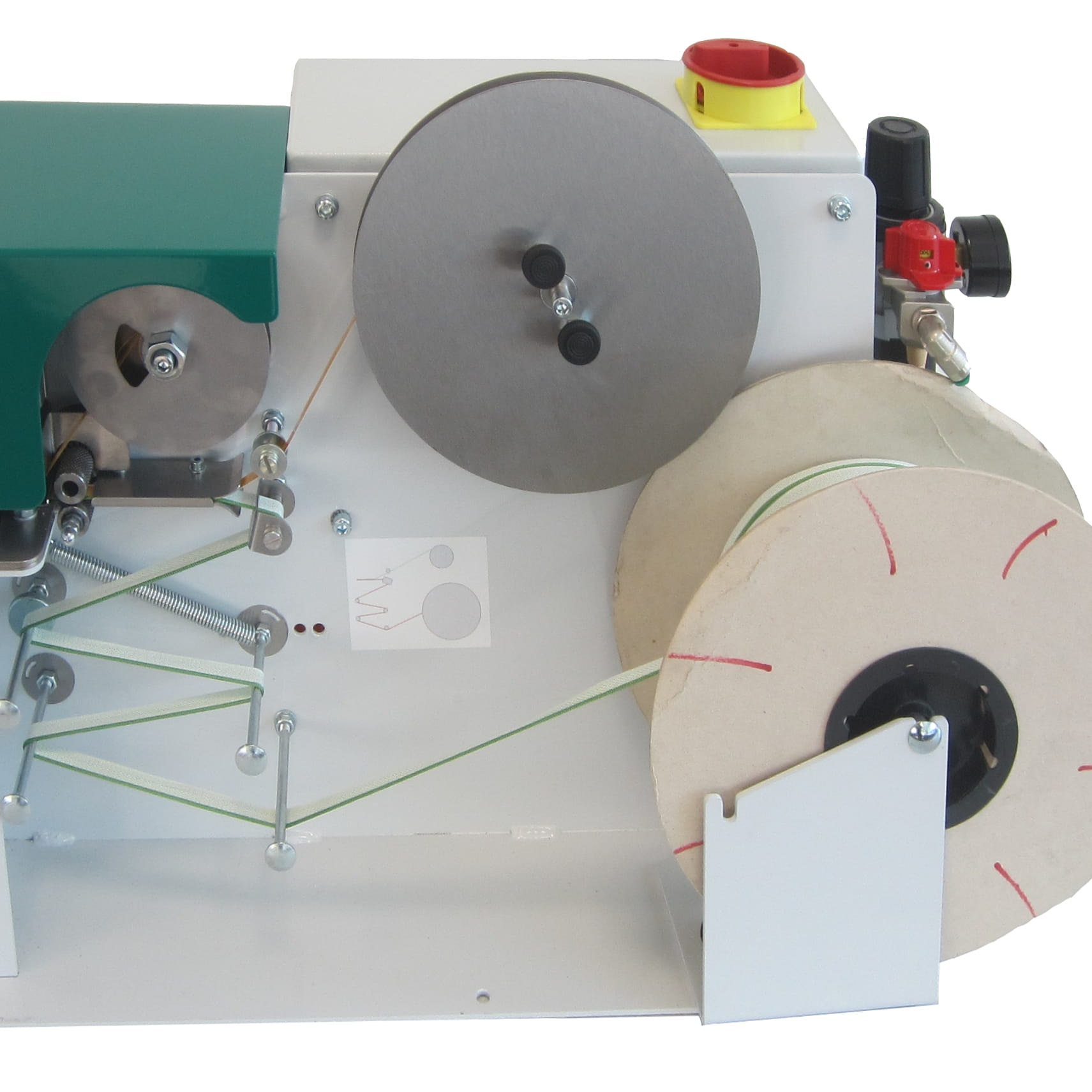

Thread-stitching machines provide very stable binding, but they are also more cumbersome and less productive than perfect binders. We do not sell thread-stitching machines that would be designed for the industrial production of books, but we can assist with our expertise in selecting a suitable machine. Even with thread-sewn books, the endsheets should not be forgotten - our PräziGard enables the subsequent attachment of endsheets to thread-sewn book blocks.

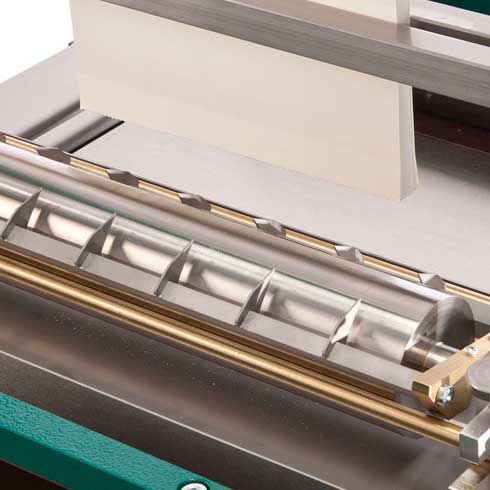

Fan binders like our PräColl meet the requirements of traditional bookbinders. Hardcover books with straight and round spines can be produced using these machines. They are largely manual tools, but this makes them more cost-effective than a semi-automatic perfect binder and, with the right handling, they can also produce a high number of copies.

Special bindings like the Layflat binding meet the high demands of photo books. For this purpose, we have developed the PräziBind layflat binding system - a cost-effective alternative to produce short runs or Books-On-Demand in lay-flat.