PräKant | Turning-in machine

Desktop machine

The PräKant is a turning-in machine designed to turn in and press down the edges during the production of book covers and other products and may also be used for rubbing down laminated or mirrored covers. 12 different programmes for turning-in and pressing down with different ways of ejection and two speeds are available integrate the machine perfectly into the workflow. The brush height of the machine may be adjusted individually to adapt to different materials and especially to the board thickness. The thinner and/or softer the board, the higher the value has to be set. All kinds of different products may thereby be turned in at optimum quality.

Process

- After gluing the cover boards and the spine (e. g. on our PräDeck or in the PräDeka system) the open case is inserted into the intake slot with its long side first. Air is fed automatically to ensure easy insertion of the cover.

- Correct positioning of the cover is indicated by green blinking of the operator button.

- As soon as the case is pushed far enough into the machine, the turning-in process is started automatically.

- The case is pulled in and the first edge is turned in. Then the case is pulled in completely.

- The cover material is pressed on to the boards and the second edge is turned in.

- Then the case is ejected to the front on to the table. Now the four corners need to be tucked in manually. The case is then turned by 90° and re-inserted into the slot with its short side first, and the two remaining edges are turned in.

- Depending on the preselected programme, the finished book case is ejected either to the front or rear of the machine.

| Dimensions | |

| Depth (mm): | 1110 |

|---|---|

| Height (in mm): | 340 |

| Weight: | 65 kgs |

| Width (in mm): | 970 |

| Output | |

| Output (pcs/h): | 100 |

| Output level: | Level 1: up to 100 pcs/h |

| Format range | |

| Board thickness (mm): | 1,2 - 3,5 |

| Case height: | 120 - 644 mm |

| Case width: | 120 - 664 mm |

| Connectors | |

| Air pressure supply (bar): | 6 |

| Power supply: | 230-240 V / 50-60 Hz |

| Other properties | |

| Category: | Case Making |

| NB: | Part of entry-level case-making system PräDeka |

| Scope of delivery: | Basic machine, 2 extension tables |

Login

Below you can see questions that other customers have asked about this product. Do you have a question of your own? Then feel free to ask us using the button below. You decide whether your question may be published.

Advantages

With the PräKant, it is possible to turn-in edges without set-up times. The simple handling allows operation without prior technical knowledge. Single-part, multi-part and asymmetrical covers with widths of up to 66.4 cm and board thicknesses of up to 3.5 mm can be processed. The productivity of the machine can be expanded as needed with additional special equipment.

Constantly changing formats can be produced without format settings.

No previous technical knowledge is necessary.

Rotary switch allows each user to easily adjust settings.

Enables processing of covers with width of up to 66.4cm and boards with thickness of up to 3.5mm.

One-piece, multi-piece & asymmetrical products possible. Also suitable for difficult materials.

The productivity of the PräKant can be increased by additional special equipment.

Constantly changing formats can be produced without format settings.

No previous technical knowledge is necessary.

Rotary switch allows each user to easily adjust settings.

Enables processing of covers with width of up to 66.4cm and boards with thickness of up to 3.5mm.

One-piece, multi-piece & asymmetrical products possible. Also suitable for difficult materials.

The productivity of the PräKant can be increased by additional special equipment.

Combined in our entry-level solution

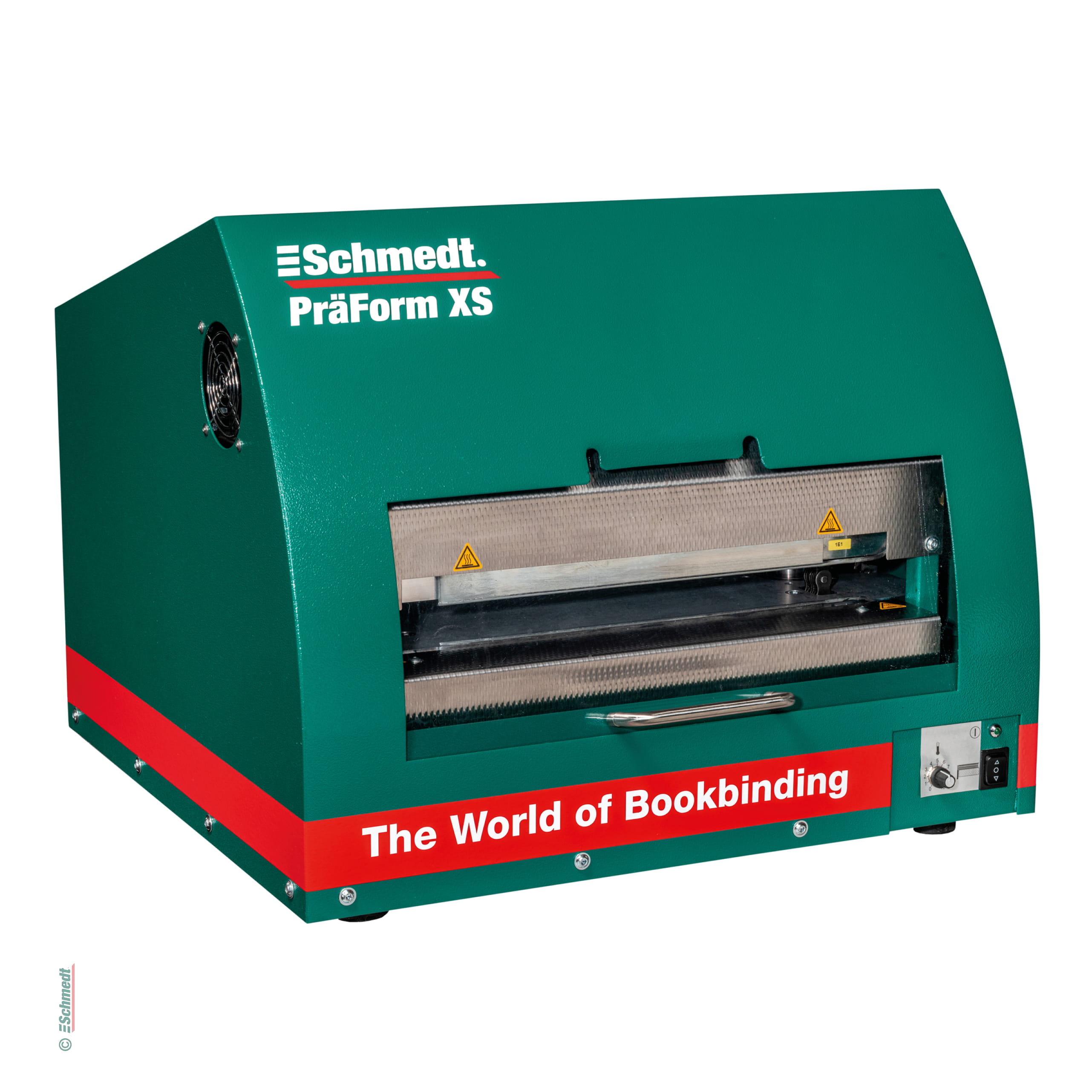

We offer the PräKant both individually and in combination with the PräDeck, PräziCoat and PräVis in the PräDeka system as well as part of our entry-level solution for the production of hardcover books (PräDeka system, PräForm XS, PräLeg XS). Discover all the machines from our entry-level solution here: