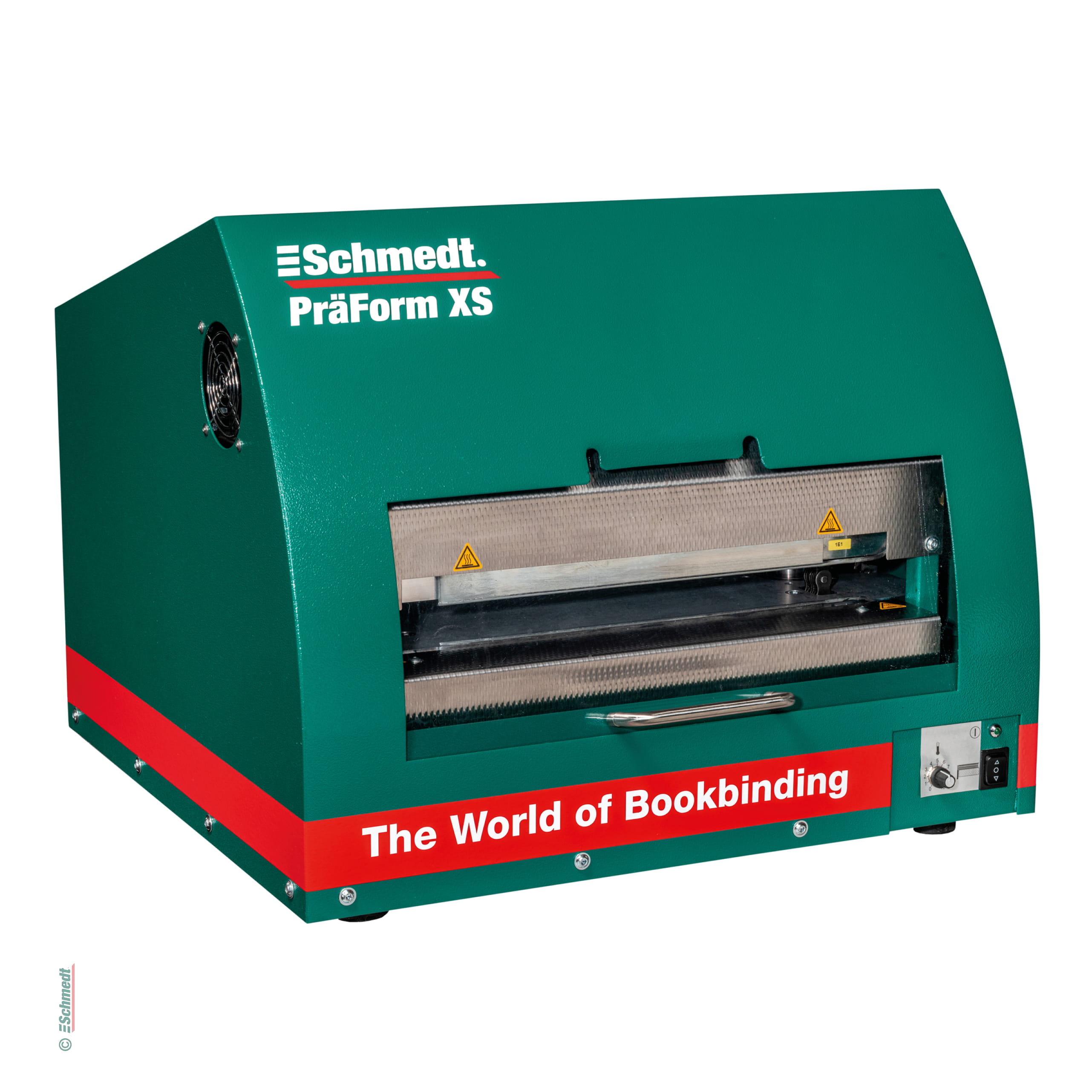

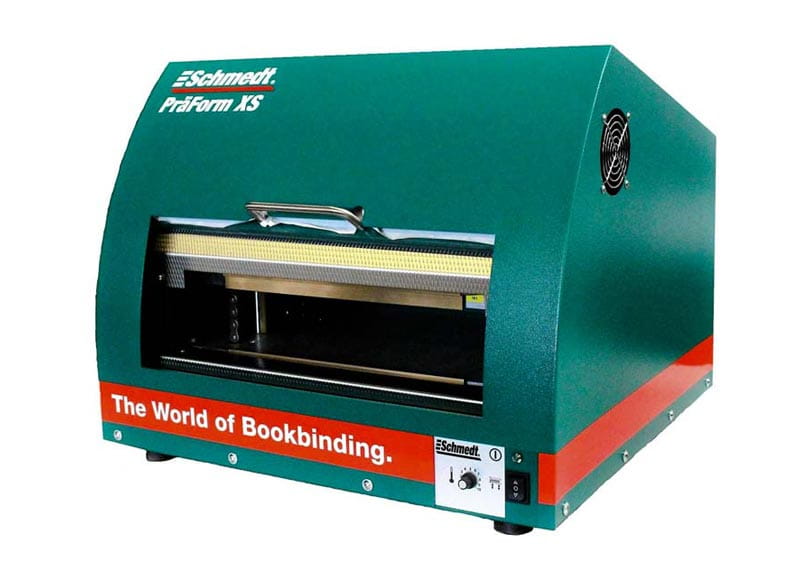

PräForm XS | Compact book press

Pressing and joint-setting machine

The PräForm XS is a machine for pressing in books after casing-in, e.g. with the PräLeg XS casing-in machine, and simultaneously setting the joint. It processes single books with changing formats as well as small series without requiring any format settings. The PräForm XS is equipped with pressing plates in 310 x 310 mm format and heated joint forming bars. Due to their rounded shape, the bars are especially suitable for cellophane and laminated papers, but also for cover materials such as fabric, bonded leather, etc. The temperature of the joint forming bars is controlled by a thermostat and can be adjusted according to adhesive properties, cover material and working speed.

Process

- After casing-in, the book is placed on the lower press plate so that the fold lies on the lower joint forming bar.

- Now the safety cover is pulled down.

- The pressing process is triggered by flicking a rocker switch upwards. During the pressing process, the next book can be cased-in.

- Flicking the rocker switch downwards ends the pressing process.

- The pressing chamber moves up. The safety cover is pushed up and the finished book is removed.

- The finished book is usually still stacked to dry out, but does not need to be pressed again.

| Dimensions | |

| Block height (mm): | 120 - 310 |

|---|---|

| Block thickness (in mm): | 2 - 75 |

| Block width (mm): | 120 - 310 |

| Depth (mm): | 600 |

| Height (in mm): | 490 |

| Weight: | 92 kgs |

| Width (in mm): | 600 |

| Output | |

| Output (pcs/h): | 80 |

| Output level: | Level 1: up to 100 pcs/h |

| Format range | |

| Block height (mm): | 120 - 310 |

| Block thickness (in mm): | 2 - 75 |

| Block width (mm): | 120 - 310 |

| Connectors | |

| Power supply: | 230 V - 50 Hz |

| Other properties | |

| Category: | Casing-In, Pressing and Joint-setting |

Login

Below you can see questions that other customers have asked about this product. Do you have a question of your own? Then feel free to ask us using the button below. You decide whether your question may be published.

Advantages

The PräForm XS fits on any work surface, making it an ideal machine for small businesses. Just like the large PräForm, the PräForm XS has intuitive and user-friendly operation. The temperature of the joint forming bars can be flexibly configured and enables perfect joints to be formed. Simultaneous pressing and joint-setting in one operation optimises your workflow. The PräForm XS is ideally matched to the PräLeg XS mounting machine and enables efficient operation by one person. Small and medium runs as well as constantly changing formats can be processed without requiring any additional format set-up.

Process small and medium runs as well as constantly changing formats without format settings.

Precise pressure and heat transfer produce perfect-looking joints.

The PräForm XS requires very little space and can be placed on any worktable.

Temperature controller enables correct setting depending on material, adhesive and working method.

Optimisation of your processes by pressing and joint-setting in one operation.

The PräForm XS is ideally matched to the PräLeg XS casing-in machine.

Process small and medium runs as well as constantly changing formats without format settings.

Precise pressure and heat transfer produce perfect-looking joints.

The PräForm XS requires very little space and can be placed on any worktable.

Temperature controller enables correct setting depending on material, adhesive and working method.

Optimisation of your processes by pressing and joint-setting in one operation.

The PräForm XS is ideally matched to the PräLeg XS casing-in machine.

Combined in our entry-level solution

We offer the PräForm XS both individually and in combination with the PräLeg XS (casing-in of book blocks into book cases) and as part of our entry-level solution for the production of hardcover books (PräDeka system, PräForm XS, PräLeg XS). Discover all machines from our entry-level solution here: