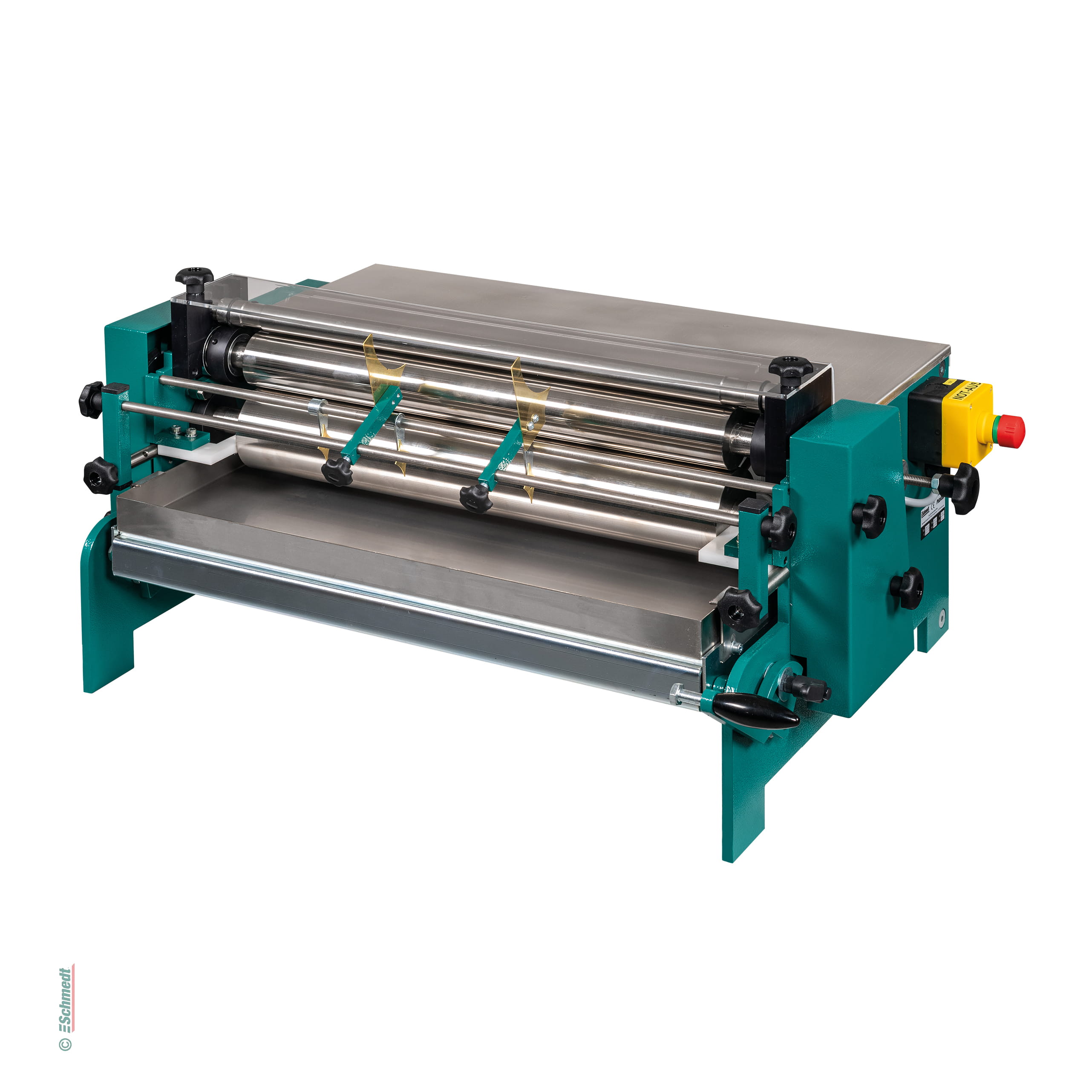

PräziCoat | Two-roller gluing machine

for cold and hot glue

Roller width: 400 mm

In stock, deliverable at short notice

The PräziCoat is a solid two-roller gluing machine for both cold and hot glue and thanks to its belt drive, it stands out for its extremely smooth and vibration-free running. The glue layer is extremely thin and even thanks to the harmonized size and speed of the dip roller and the coating roller. The thickness of the glue layer may be adjusted by modifying the distance of the two rollers to one another by means of a hand lever. The speed of the glue rollers is continuously adjustable. Moreover, the PräziCoat is equipped with two overlying pressure rollers so that even cardboard and board may be processed. For processing hot glue, as required for example for the case-making with laminated cover material, the PräziCoat may be equipped with an optional automatic water feed (PräVis).

The machine may be cleaned very easily. When using hot glue, the glue tray is lowered and superfluous glue is wiped off the rollers and then rinsed with water. Then the machine is simply cooled down. When using cold glue, the tray is filled with water and the turning rollers clean themselves.

The machine is available in three sizes: PräziCoat 400 - 400 mm roller width, PräziCoat 520 - 520 mm roller width, PräziCoat 720 - 720 mm roller width. In our PräDeka system, the PräziCoat 400 is used.

Process

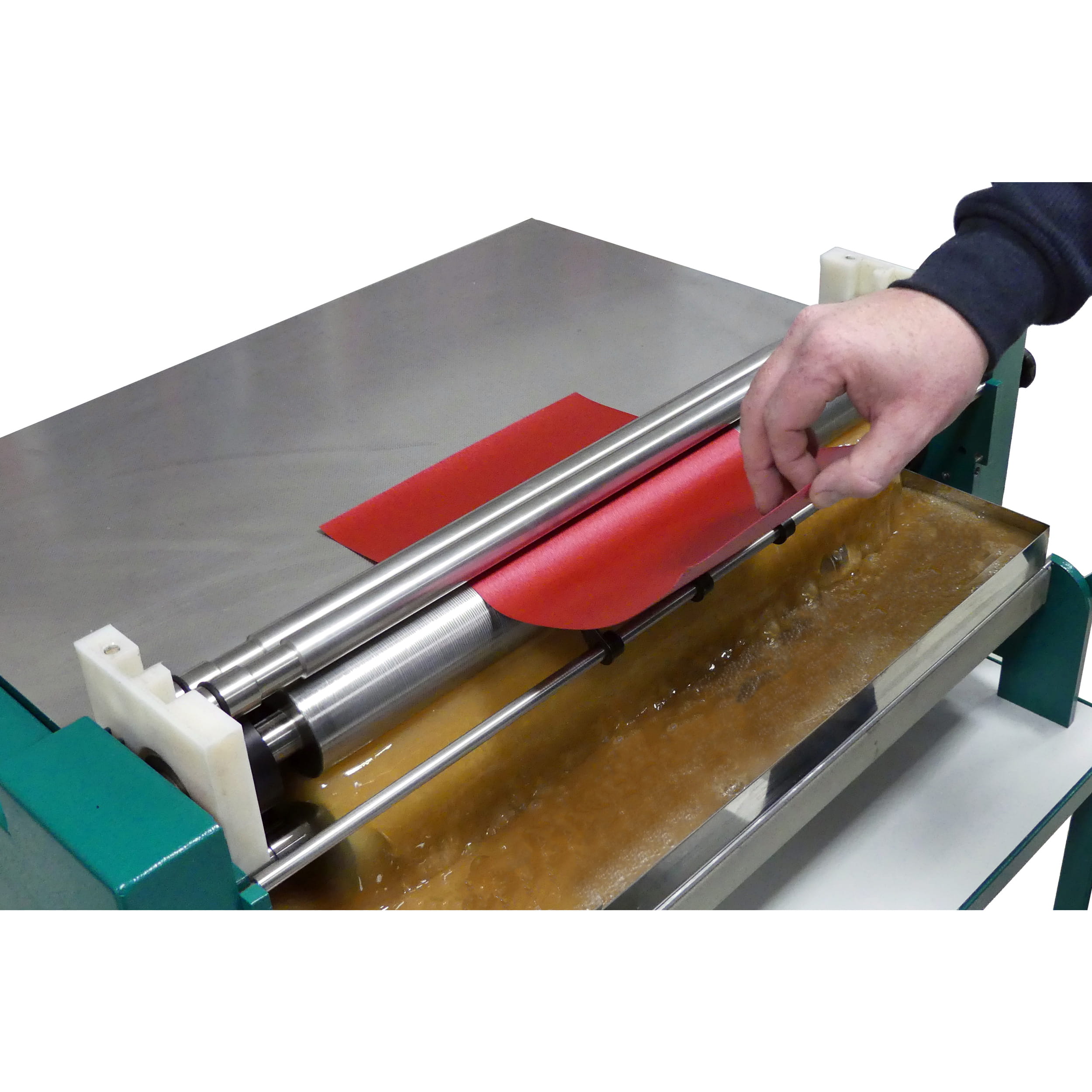

- Glue is filled or placed in the glue tray.

- In the case of cold glue, the viscosity is then adjusted by adding water.

- In the case of hot glue, the glue tray is heated and the viscosity is also adjusted by adding water.

- Water should be added regularly to keep the viscosity constant, as this is influenced by environmental factors such as heat and humidity.

- Once the adhesive is ready for processing, the operator can feed the cover material. This is fed to the infeed rollers and automatically forwarded to the top glue application roller.

- Pickers lift the glued sheet from the applicator roller.

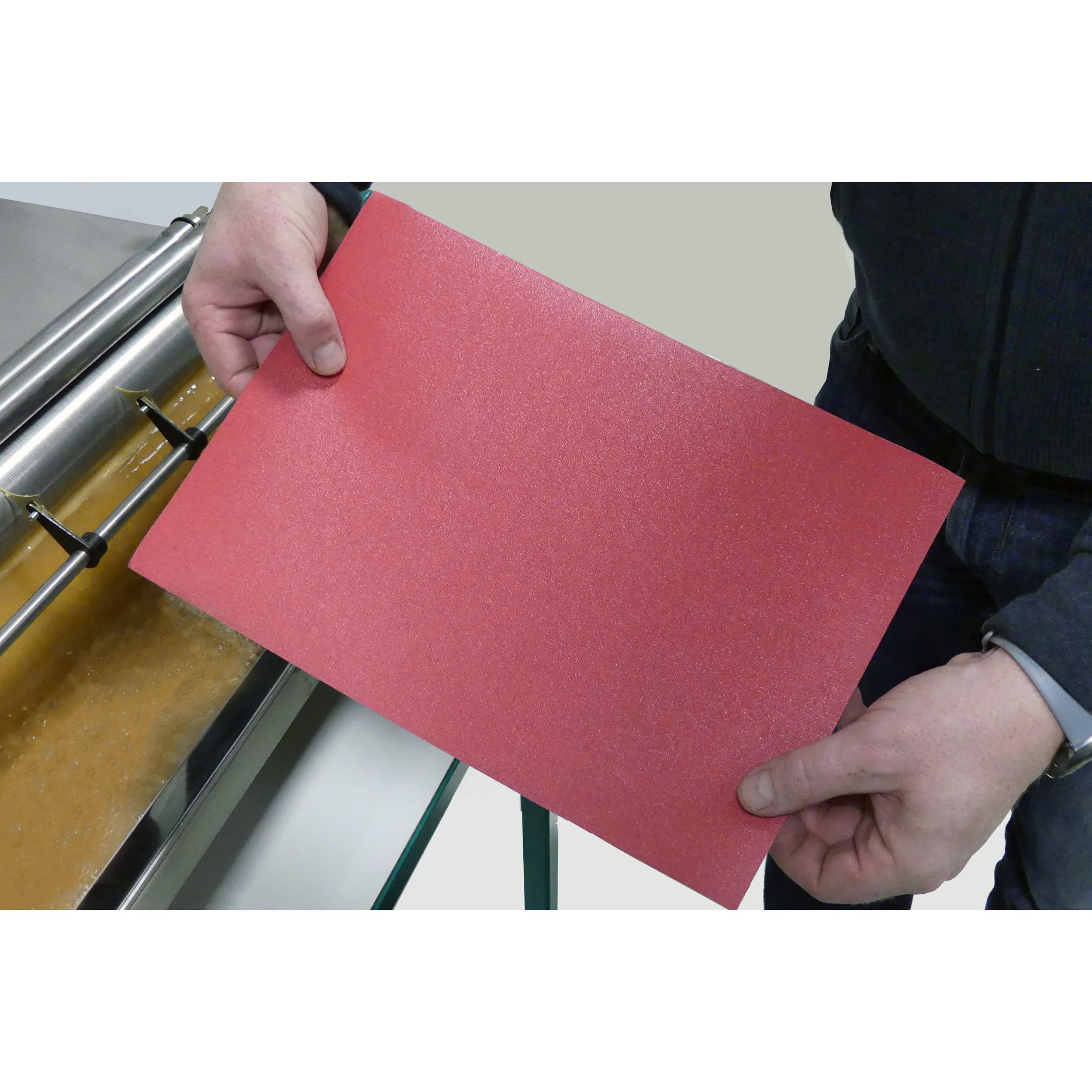

- The operator receives the single-sided glued cover material.

- The material can then be processed immediately.

| Dimensions | |

| Depth (mm): | 620 |

|---|---|

| Height (in mm): | 400 |

| Weight: | 75 kgs |

| Width (in mm): | 770 |

| Technical details | |

| Type: | 400 |

| Connectors | |

| Power supply: | 230 V / 50 - 60 Hz (AC) |

| Other properties | |

| Category: | Case Making, Gluing |

Login

Below you can see questions that other customers have asked about this product. Do you have a question of your own? Then feel free to ask us using the button below. You decide whether your question may be published.

Quelle colle est préférable pour utiliser dans l'encolleuse car la Planatol BB mousse énormément

Advantages

The PräziCoat is suitable for hot and cold glue. The rollers, table and basin are made of stainless steel, which prevents rust when working with water and glue. At the same time, it offers the machine a certain robustness.

Using the control panel at the bottom left of the machine, the temperature and speed can be regulated as desired. The glue is applied evenly. In addition, the processing of high grammages is possible due to the contact pressure rollers.

After use, the PräziCoat can be cleaned effortlessly with standard household utensils.

Both hot and cold glue can be processed, depending on preference and processes.

Rollers, table & basin are made of stainless steel, making the machine robust and rust-resistant.

As a result, the machine works extremely quietly and runs smoothly.

The speed & temperature can be regulated electrically, smoothly via the control panel (left).

The final cleaning is easily done with simple utensils.

An even layer of glue is applied to the binding material.

The processing of cardboard and paperboard is possible due to adjustable pressure rollers.

A ventilation system prevents the formation of condensation water (with warm glue).

Both hot and cold glue can be processed, depending on preference and processes.

Rollers, table & basin are made of stainless steel, making the machine robust and rust-resistant.

As a result, the machine works extremely quietly and runs smoothly.

The speed & temperature can be regulated electrically, smoothly via the control panel (left).

The final cleaning is easily done with simple utensils.

An even layer of glue is applied to the binding material.

The processing of cardboard and paperboard is possible due to adjustable pressure rollers.

A ventilation system prevents the formation of condensation water (with warm glue).

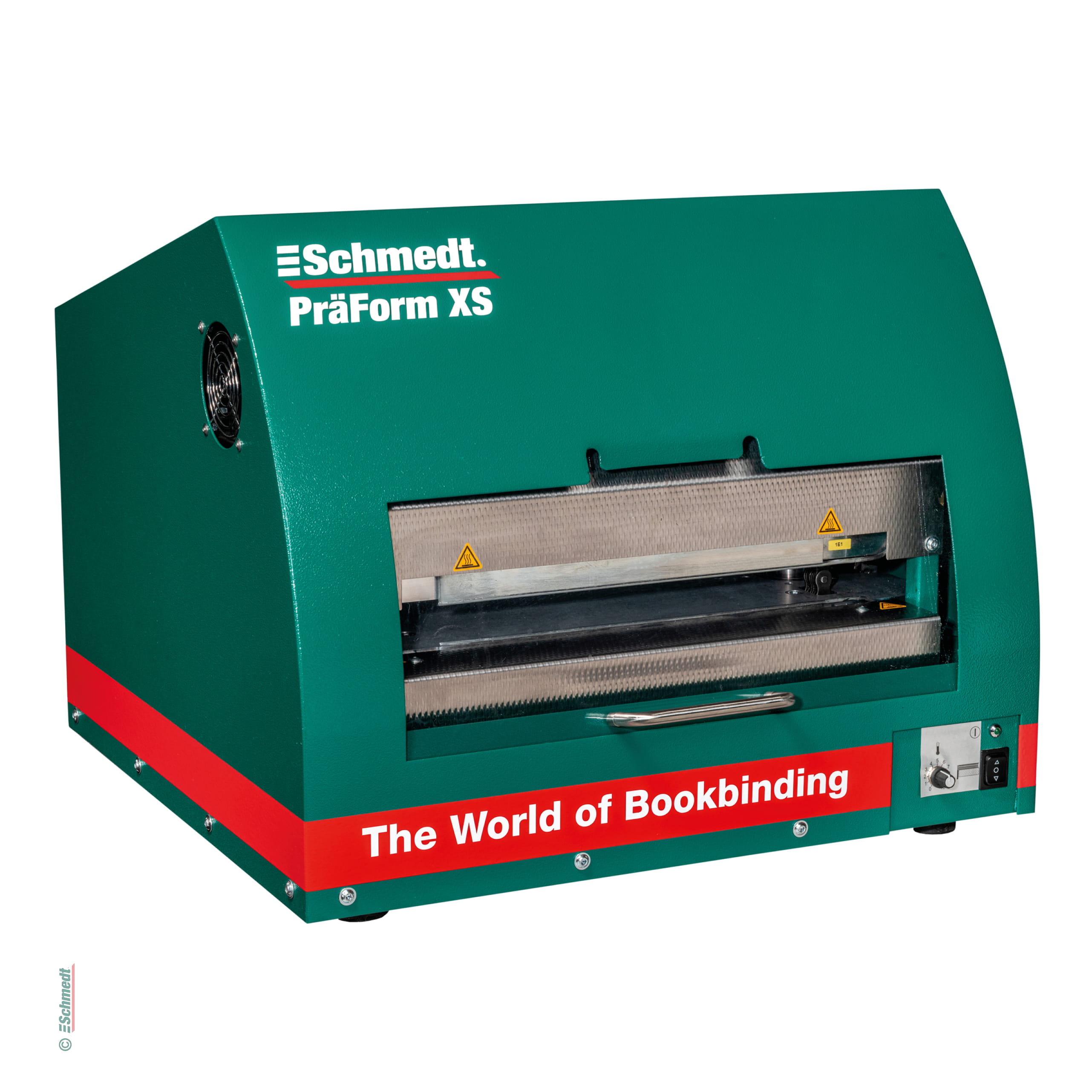

Combined in our entry-level solution

We offer the PräziCoat both individually and in combination with our viscosity optimisation PräVis (combined with PräDeck and PräKant in the PräDeka system) as well as part of our entry-level solution for the production of hardcover books (PräDeka system, PräForm XS, PräLeg XS). Discover all the machines from our entry-level solution here: