PräDeka XL | Case-making machine

Semi-automatic casemaker for hardcover cases

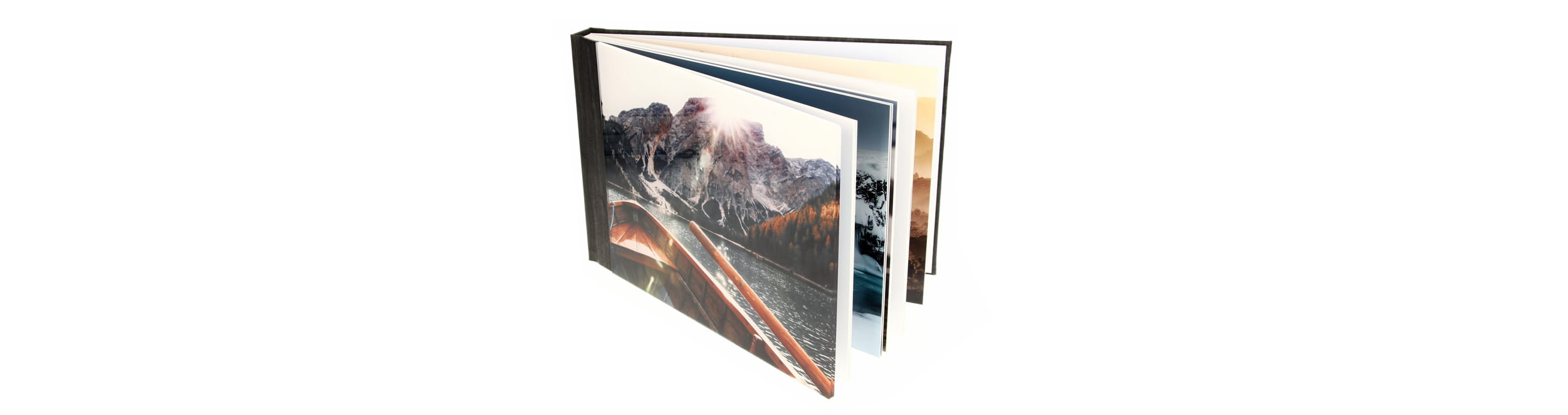

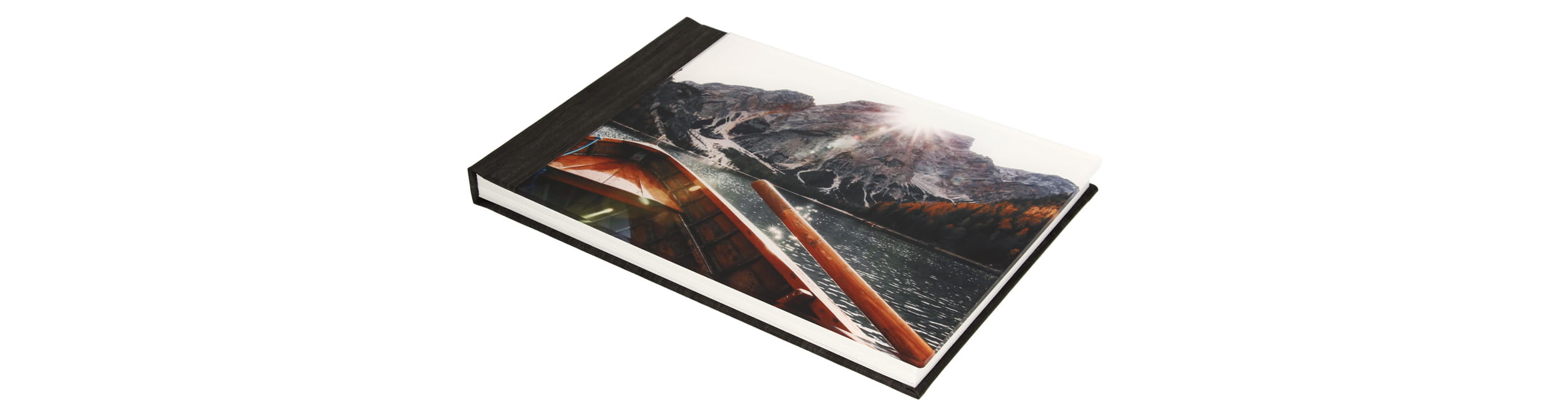

The PräDeka XL is a semi-automatic machine for the production of one-off and multiple book cases. Formats from 15 x 15 cm up to 52 x 110 cm may be processed. With hardly any setup time runs of 1 - 500 pieces or more can be produced economically. The machine is operated by one person, who glues the cover material (on a separate gluing machine, e. g. PräziCoat), puts the boards into place and tucks in the corner and in a second work step, turns and repositions the case for turning in the two remaining edges. The actual casemaking process, i.e. turning in all four edges and pressing the case is done automatically. Besides book cases almost any turned-edge product with single-, triple-, multi-part or asymmetric cases may be processed, among them cases for ring binders, menu covers, photo albums, folders, calendar backs and gameboards.

Process

- Basic settings are edited on the touchscreen display. If the basic settings are to remain unchanged, no new entries are necessary. Production may be started immediately.

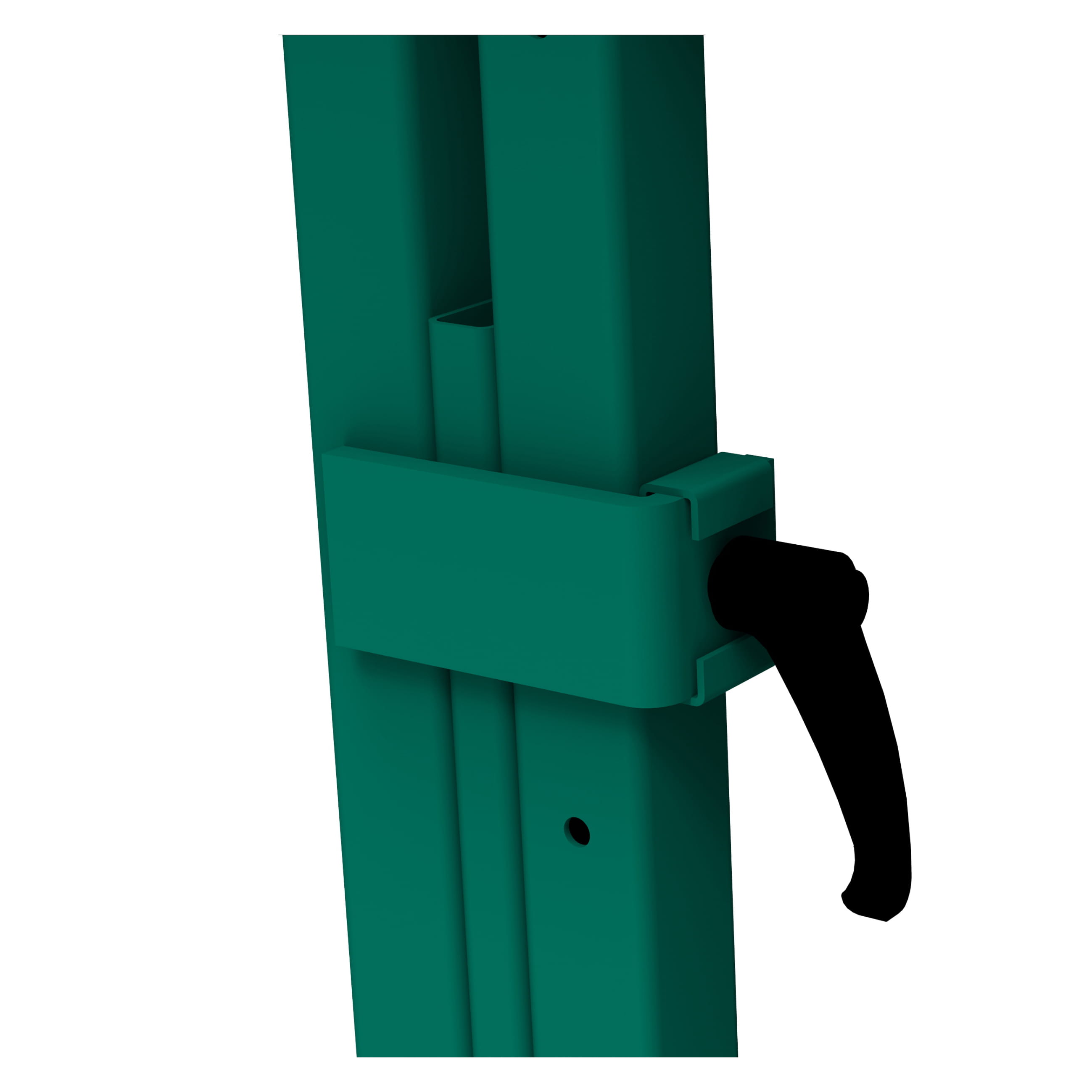

- First the cover material with trimmed corners is glued on a separate gluing machine and placed on the machine's suction table. The upper overlap of the turn-in (20 mm standard, 15 mm optionally) is preset by a stop bar. Lateral adjustment is done by means of a centered scale on the stop bar. When producing multiple cases (of the same size), side stops facilitates alignment. By pressing the cycle button, the joint bars are lowered on to the cover material. The spine hollow is placed manually between the joint bars, and the two boards are placed abutting the guide angle.

- Now the working cycle is started by pressing one of the green buttons or by pressing the foot pedal. This will raise the stop bar and the joint bars, carry the cover/board assembly into the machine where it is collected by the first pair of rollers which forward it to the turning-in brush. One long edge is turned in. The case is forwarded to the second pair of rollers which lead it to the turning-in brush from the other side. The second long edge is turned in, and the case is led back to the front of the machine.

- The operator now tucks in the corners manually, turns the case by 90°, pushes it against the back stop. By pressing one of the green buttons or by pressing the foot pedal, the case is pulled in with its short side first, and the first short edge is turned in. The case is transported to the second pair of rollers which again lead it to the turning-in brush from the other side, and the second short edge is turned in. Then the ready case leaves the machine either towards the front or the rear. During each process, i. e. four times in total, the book case is pressed by the pairs of rollers, so that even difficult materials are pressed efficiently.

- Even after short training only, an output of approx. 120 cases per hour may be achieved.

| Dimensions | |

| Depth (mm): | 1300 |

|---|---|

| Height (in mm): | 1250 |

| Spine width (mm): | 5 - 85 |

| Weight: | 380 kgs |

| Width (in mm): | 1400 |

| Output | |

| Output (pcs/h): | up to 120 |

| Output level: | Level 2: 101 - 200 pcs/h |

| Format range | |

| Board thickness (mm): | 1,2 - 3,5 |

| Case height: | 150 - 520 mm |

| Case width: | 150 - 1100 mm |

| Spine width (mm): | 5 - 85 |

| Connectors | |

| Air pressure supply (bar): | 6 |

| Electric power: | 500 W |

| Power supply: | 230-240 V / 50-60 Hz |

| Other properties | |

| Category: | Case Making |

| Scope of delivery: | 1 Set of stops for 20 mm turn-in, 1 set of joint bars 8mm |

Login

Below you can see questions that other customers have asked about this product. Do you have a question of your own? Then feel free to ask us using the button below. You decide whether your question may be published.

Advantages

The large PräDeka XL case-making machine is just as easy to operate as the small PräDeka. No prior technical knowledge is required. As a rule, there are no set-up times. In general, a very large format range from 15 x 15 cm to 52 x 110 cm can be processed on the machine, making it predestined for photo books, sample books or menus. In addition to very large formats, the processing of difficult materials is another speciality of the PräDeka XL.

Constantly changing formats can be processed without format settings.

Working with cardboard up to 3.5 mm thick is possible without any problems.

User-friendly, multilingual menu allows any user to operate.

The material is sucked in via the vacuum table so that it does not slip or curl.

All formats with width from 15cm to 110 cm can be processed.

The simplicity of operation allows even non-professionals to operate the machine.

Constantly changing formats can be processed without format settings.

Working with cardboard up to 3.5 mm thick is possible without any problems.

User-friendly, multilingual menu allows any user to operate.

The material is sucked in via the vacuum table so that it does not slip or curl.

All formats with width from 15cm to 110 cm can be processed.

The simplicity of operation allows even non-professionals to operate the machine.

Solution for photo books and XXL formats

The PräDeka XL is the centrepiece of our solution for photo books and XXL formats. It works optimally with the PräLeg (casing-in of book blocks into book covers) and PräForm (pressing and joint-setting):

Ideally combined with PräLeg & PräForm

Our casing-in solution for single-unit production and small series consisting of the two machines PräLeg and PräForm enables the production of a high-quality, neatly cased-in book with a burnt-in joint and excellent opening performance - and all this with a realistic productivity of 150 books per hour for changing formats. Both machines allow processing of DIN formats from A6 to A3 portrait & landscape.

Go to PräLeg Go to PräForm