PräLeg | Book casing-in machine

Machine to combine book blocks with book covers

The PräLeg is our tried and tested casing-in machine that we are continuously improving. With its well-coordinated sequence control, the PräLeg can be used for casing-in within bookbinderies manufacturing short-run and widely varying size books, as well as for series production in industrial bookbinderies and printing works. The machine operates on the proven principle of one blade for holding and transporting the book block between the gluing units. Largely without a need for format settings, small and medium-sized editions can be processed just as easily as special-sized and constantly-changing formats. Control of specific procedures at the gluing stage and subsequent transport of the block to the case is controlled by touchscreen. This facility can be used to adapt the gluing process to a variety of block types (e.g. photo albums) and to different kinds of backliner. The glue feed into the gluing units is controlled by pumps. To achieve a pefect viscosity of the glue, an automatic water feed is integrated into the machine. Water can be added to the glue in intervals either automatically or manually. The machine also has an automatic cleaning system which is activated by touchscreen.

Process

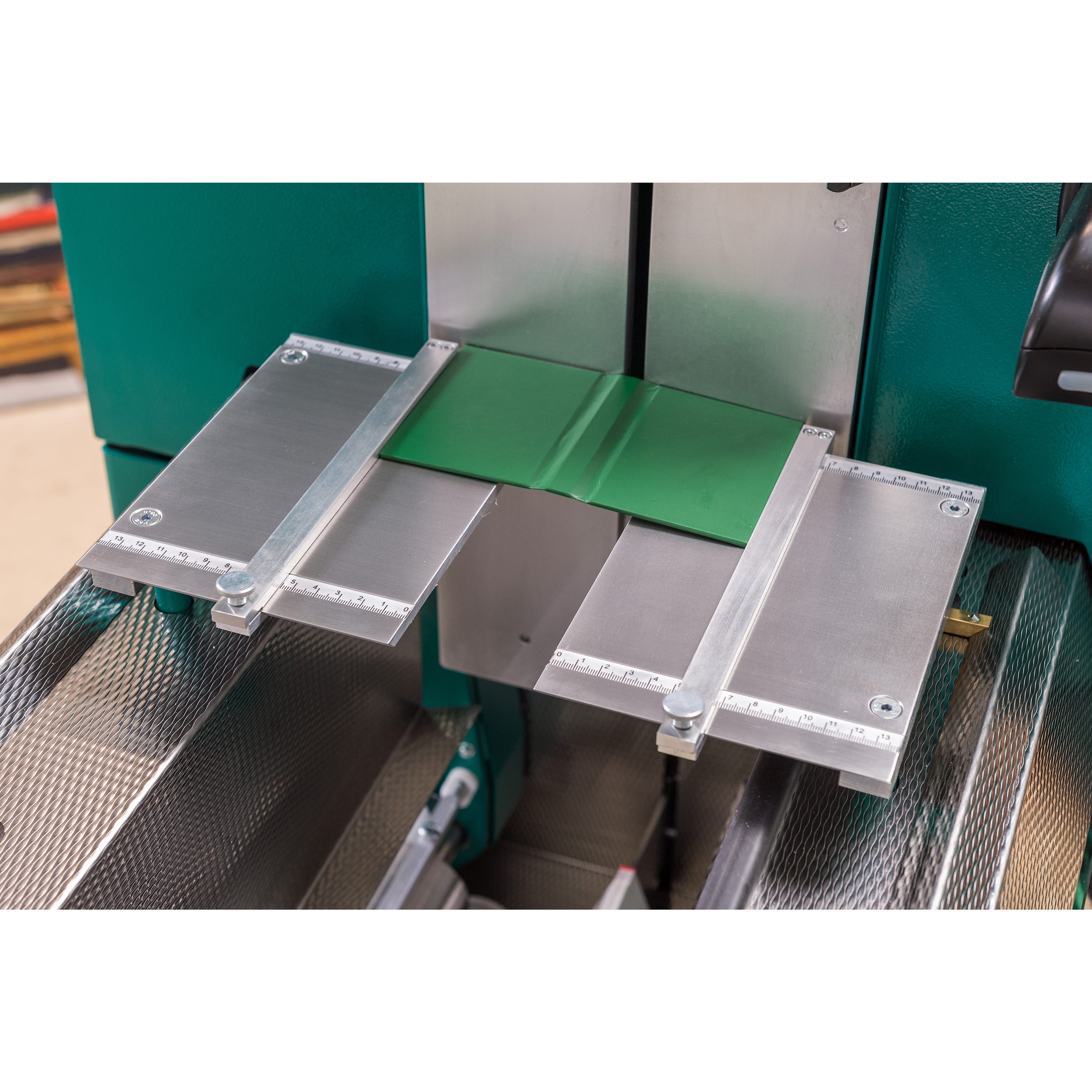

- The machine has two separate gluing units for applying glue to the two end papers of the book block. The glue is fed into the gluing units by pumps.

- At the start of the operating cycle the blade is located in the upper position. A book block is opened in the centre, placed on the blade and pushed against the rear limit stop.

- The casing-in cycle can then be triggered by the operator. The blade drives downwards between the gluing units. While the blade is travelling downwards the book case is placed in the case mountings. It is automatically centred by means of these mountings. A back stop ensures that the upper and lower cover-rim overlaps (or squares) are equal.

- When the blade has reached the gluing position the gluing units come together pressing briefly against the book block in the area of the joint. The machine control ensures that the spread of glue is slightly thicker in the joint area. The additional glue applied to the joint can be regulated independently of the normal spread thickness, thereby adjusting the glue level to suit the overlap of mull. The length of the additional gluing surface can also be set via the control unit, so that even widely overlapping mull represents no problem.

- After the pressing of the rollers against the joint, the blade begins to move upwards and glue is applied to the two endpapers. The speed at which the blade travels matches precisely the rotation of the gluing rollers. This ensures the level of glue aplied to the end papers is even.

- At the end of the cycle the blade guides the book block into the case, coming to a halt in the upper position. This process is supported by pressing the case onto the book block. The book block and the case have now been bound to a book.

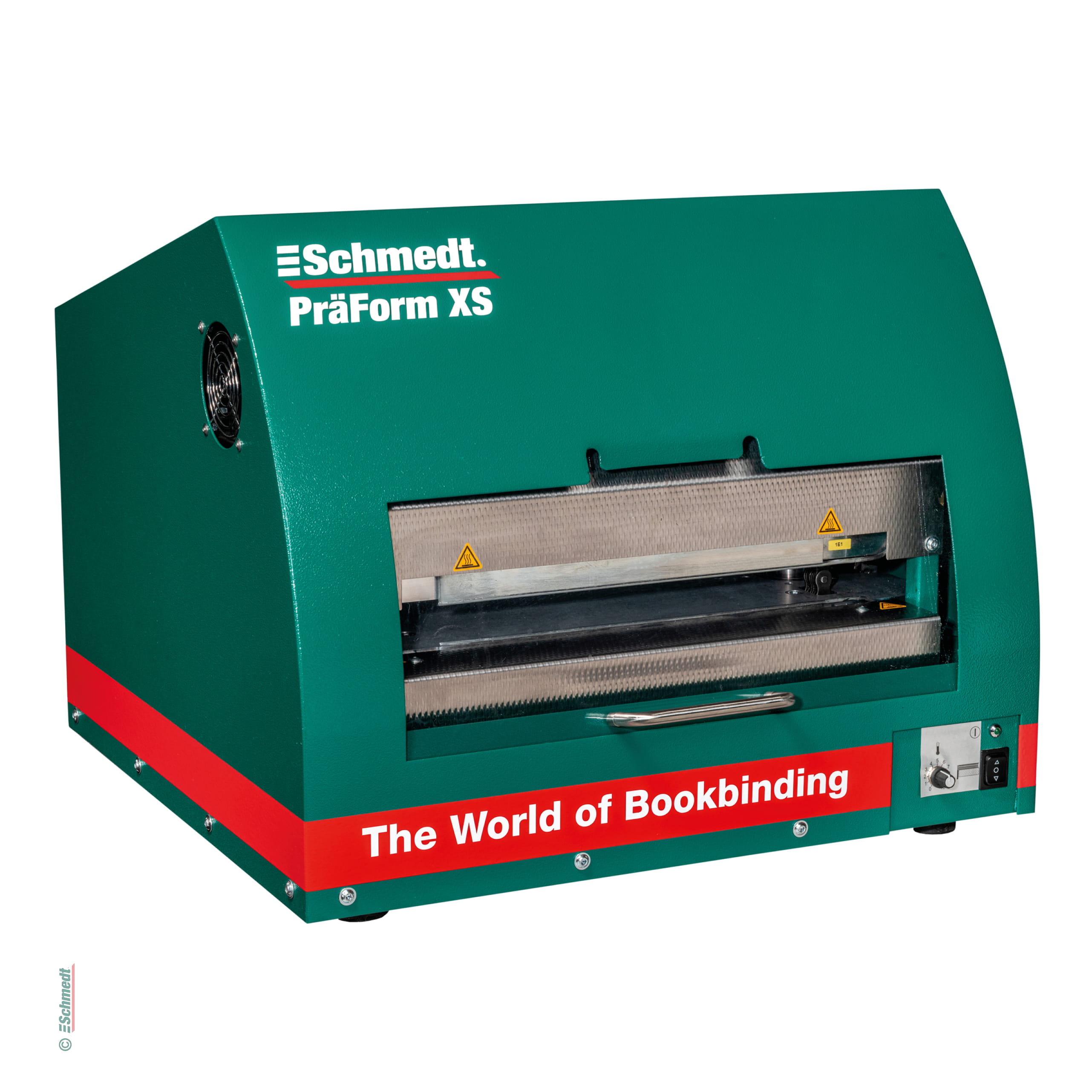

- This book is next taken from the blade and is pressed in a pressing and joint-setting machine (e.g. our PräForm or PräForm Pro).

- With its automatic cleaning system, the machine may be cleaned easily and quickly after use.

| Dimensions | |

| Block height (mm): | 80 - 450 |

|---|---|

| Block thickness (in mm): | 2 - 80 |

| Block width (mm): | 110 - 450 |

| Depth (mm): | 670 |

| Height (in mm): | 1850 |

| Weight: | 325 kgs |

| Width (in mm): | 1040 |

| Output | |

| Output (pcs/h): | 300 |

| Output level: | Level 3: more than 200 pcs/h |

| Format range | |

| Block height (mm): | 80 - 450 |

| Block thickness (in mm): | 2 - 80 |

| Block width (mm): | 110 - 450 |

| Connectors | |

| Air pressure supply (bar): | 6 |

| Electric power: | 600 W |

| Power supply: | 230-240 V / 50-60 Hz |

| Other properties | |

| Category: | Casing-In, Pressing and Joint-setting |

Login

Below you can see questions that other customers have asked about this product. Do you have a question of your own? Then feel free to ask us using the button below. You decide whether your question may be published.

Ist hier auch Leasing möglich?

Gern erstellen wir Ihnen ein Leasing-Angebot, sodass Sie schon einmal sehen können mit was für einer Rate Sie rechnen können. Sprechen Sie uns einfach an.

Advantages

Anyone looking for casing-in solutions for one-off production and smaller series in the hardcover sector cannot avoid the PräLeg. We are continuously developing this tried-and-tested casing-in machine to offer our customers the best possible solution. Set-up times are eliminated when working with the PräLeg - different materials and formats can be processed without format settings. Settings can be made very easily via the integrated touch screen. Among other things, the glue application can be adjusted to optimise processing for different types of book blocks (e.g. photo books) or backlining types (e.g. gauze). Besides standard hardcover covers, very small and soft covers can also be processed. After use, the machine can be cleaned easily and quickly thanks to an automatic self-cleaning system.

No set-up is necessary when using different materials and book formats.

After use, the machine can be cleaned quickly and easily.

Settings can be fine-tuned via the integrated touch screen.

The integrated water feed ensures that the viscosity of the glue remains constant.

The glue application can be adjusted as required (e.g. for book blocks with gauze).

A wide variety of materials and formats can be processed on the PräLeg.

Using the touch screen, the operator can pump new glue into the gluing units.

Optional barcode system enables matching of book cover and book block.

No set-up is necessary when using different materials and book formats.

After use, the machine can be cleaned quickly and easily.

Settings can be fine-tuned via the integrated touch screen.

The integrated water feed ensures that the viscosity of the glue remains constant.

The glue application can be adjusted as required (e.g. for book blocks with gauze).

A wide variety of materials and formats can be processed on the PräLeg.

Using the touch screen, the operator can pump new glue into the gluing units.

Optional barcode system enables matching of book cover and book block.

The PräLeg in combination with the PräForm

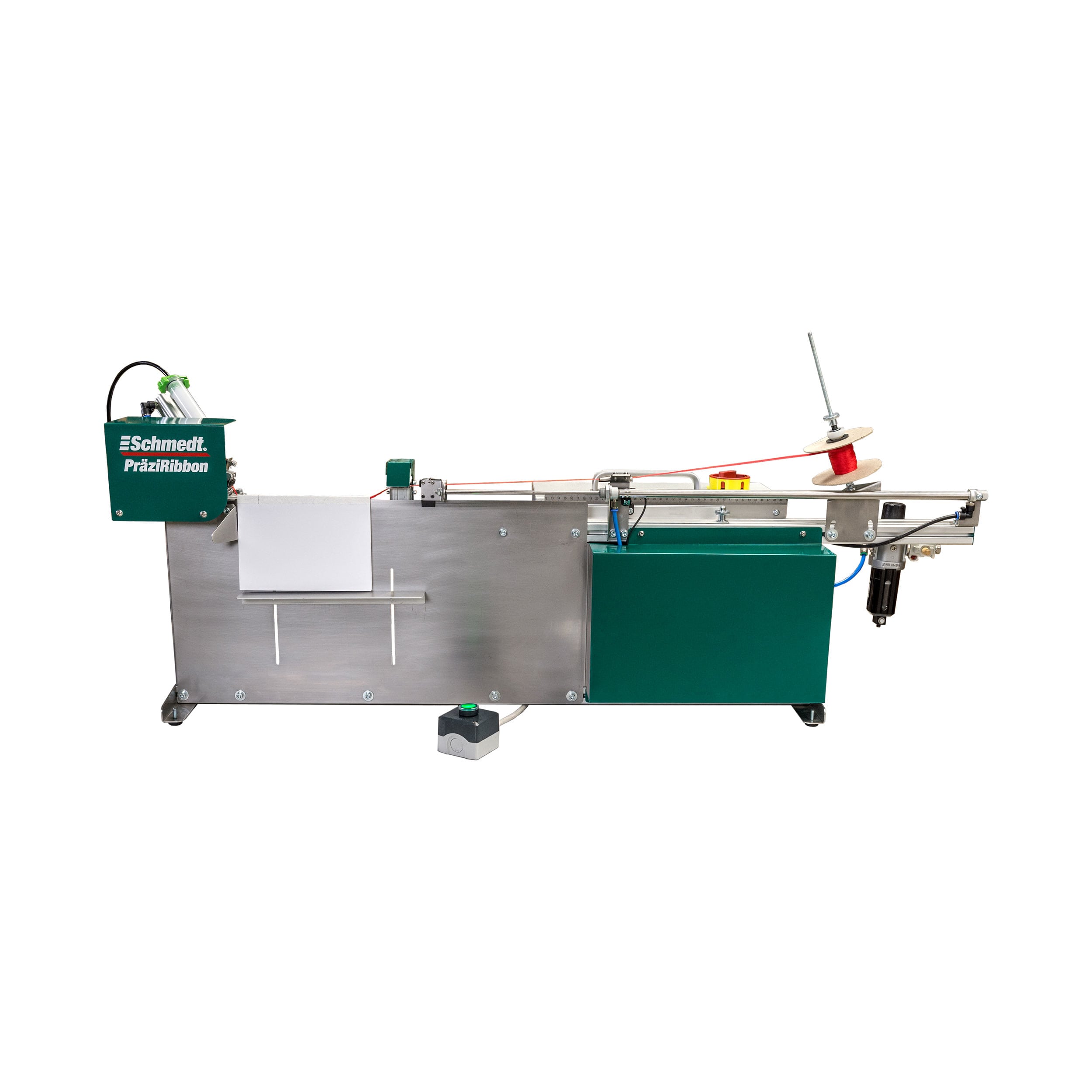

The PräLeg is a casing-in machine for the production of high volumes of hardcover books with changing formats. The PräLeg is combined with the PräForm (pressing and joint-setting) or the PräForm Pro (pressing and joint-setting with multi-station system and stacker) to produce precisely cased-in books with a beautiful joint and good opening behaviour:

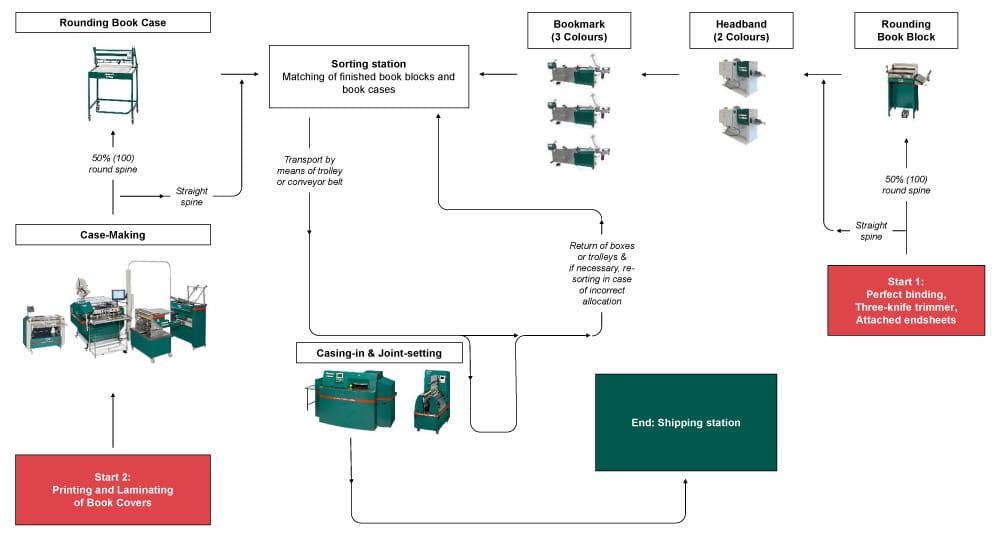

Books-on-Demand Workflow

Our scalable on-demand workflow (shown here as an example for 200 books per hour) minimises sorting effort and downtime risk (machines are designed to meet on-demand production requirements and are stand-alone; in case of problems on one machine, production can continue on the remaining machines). This example workflow takes into account the following complexity of books: 50% books with round spine, 100% books with headband (2 colours), 100% of books with bookmark (3 colours). Stations that are not required (e.g. rounding, headband, bookmark) can simply be omitted.