Cover-1 | Case-making system

Semi-automatic, barcode-controlled system

The Cover-1 system is a barcode-controlled, semi-automatic case-making system for the production of hardcovers, especially designed for the requirements in on-demand production. Each case that is processed can have a different format. The control of the format setting parameters is done automatically via a barcode reader. The format data contained in the barcode is transmitted to the devices of the Cover-1 system, which adjust to the next format according to the data. The system consists of various modules that can be combined depending on the requirements and processes to be reflected.

Process

- The Cover 1 system is operated and controlled by the central control unit PowerTower. All settings for the format are read from the barcode on the cover sheet through a barcode reader and sent to the system for direct processing.

- On the PräziTrim boards and spines for the production of book cases are trimmed fast and accurately.

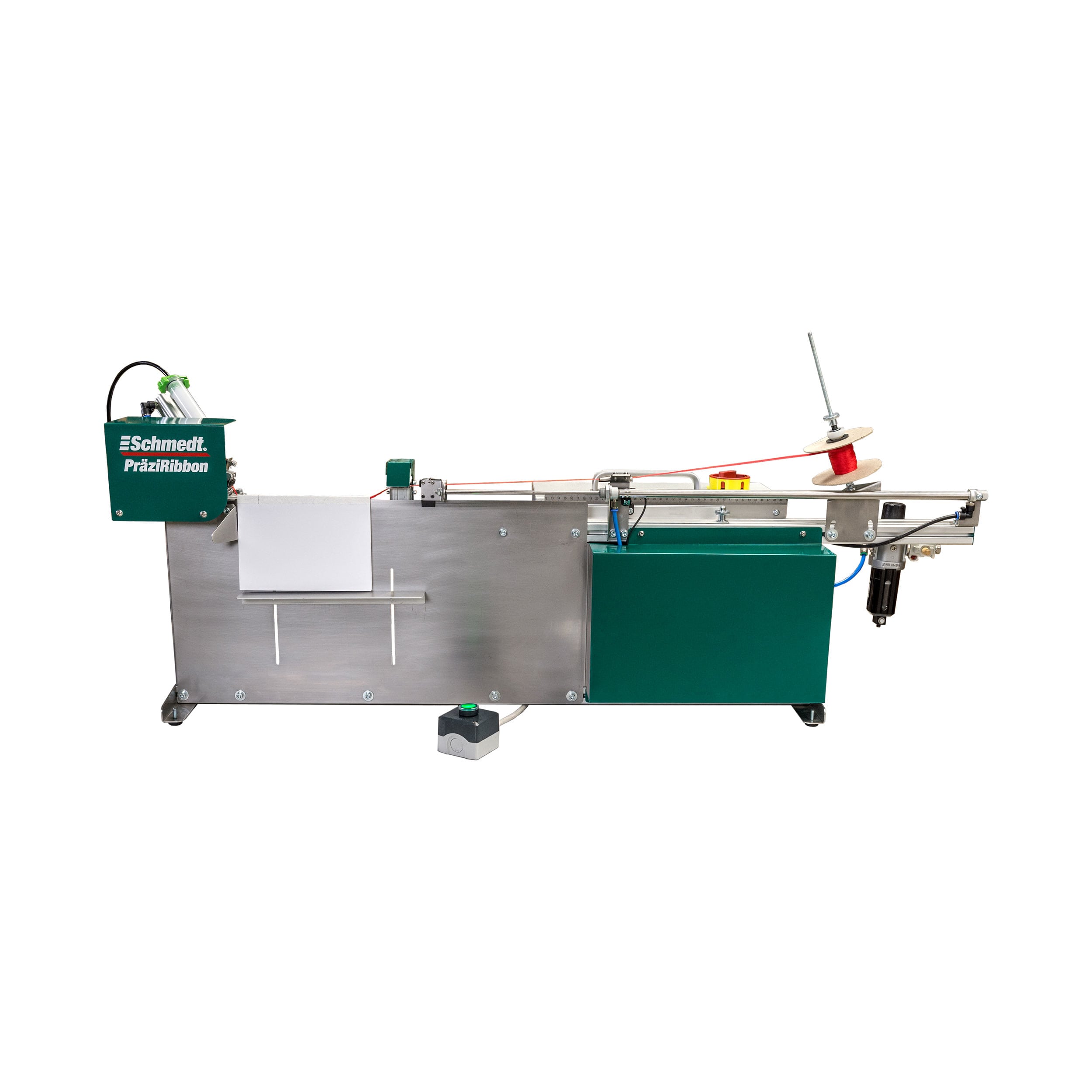

- For processing soft spines that are used in round books, the PräziSpine is recommended. This machine cuts thin greyboard rolls for flexible spines to size automatically.

- The PräziSheet is used to trim printed and/or laminated cover sheets to prepare them for case-making. The cover material must be printed with a black border representing the trim mark. The material is turned automatically and is ejected to the rear when trimmed. It is controlled by a tablet PC included in delivery.

- The PräziCoat Pro is used to glue the cover material. This gluing machine has a rotating roll of 530 mm width for the use of hotmelt gelatine. The machine has an automatic viscosity control (AVC) for permanent use without requiring operator input.

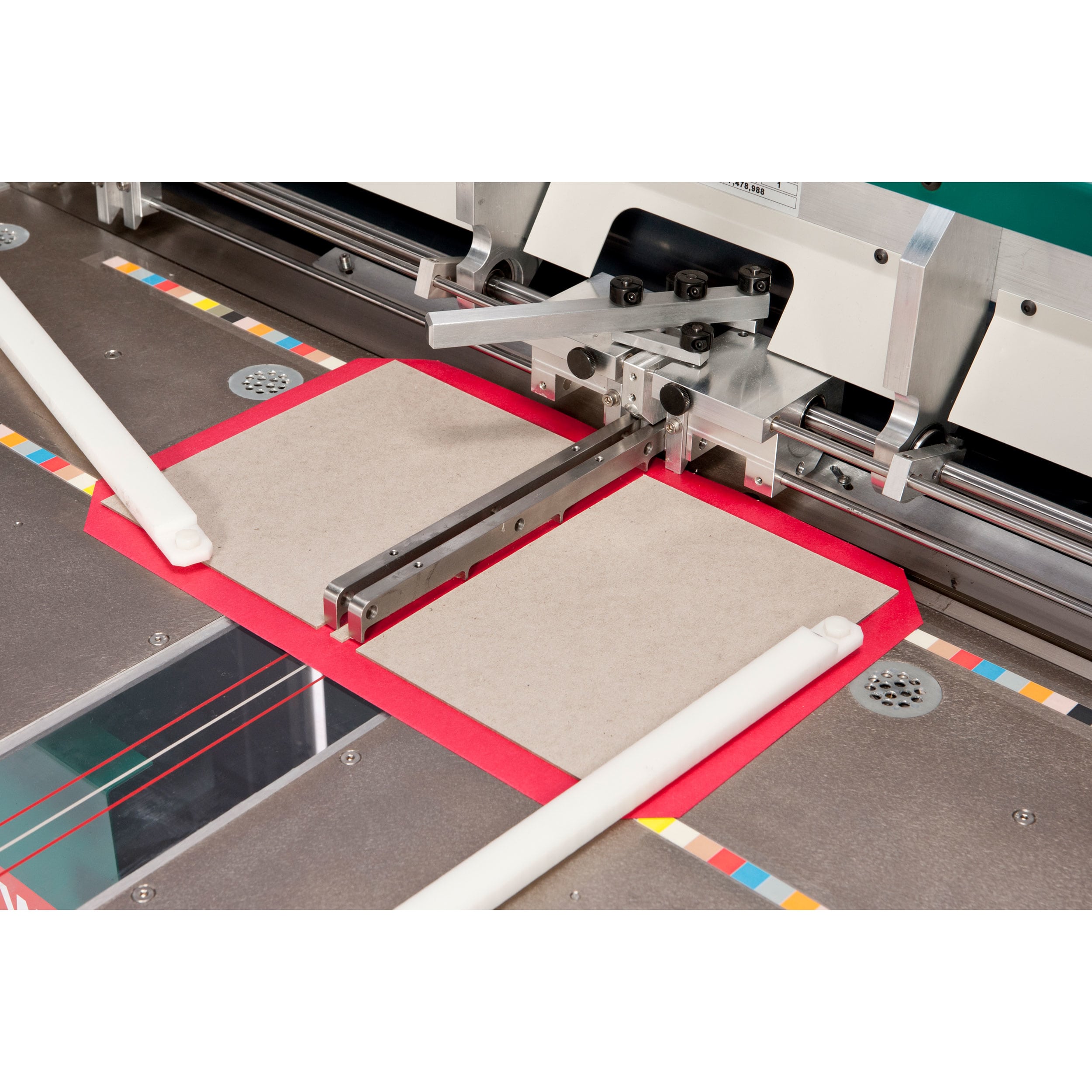

- The actual case is made on the PräziCase Pro. The operator puts the glued cover material on the machine table and places the boards manually. The actual case-making process with cutting the corners (optional), turning-in all four edges and the final pressing of the case is done fully automatically.

The components of the Cover 1 system may be combined individually according to your requirements. Moreover, all machines are available as standalone machines.

| Dimensions | |

| Spine width (mm): | 6,4 - 82 |

|---|---|

| Output | |

| Output (pcs/h): | 250 |

| Output level: | Level 3: more than 200 pcs/h |

| Format range | |

| Board thickness (mm): | 1,5 - 3,5 |

| Case height: | 170 - 400 mm |

| Case width: | 219 - 711 mm |

| Spine width (mm): | 6,4 - 82 |

| Connectors | |

| Air pressure supply (bar): | 6 |

| Nominal current: | 6 A |

| Power supply: | 230-240 V / 50-60 Hz |

| Other properties | |

| Category: | Case Making |

Login

Below you can see questions that other customers have asked about this product. Do you have a question of your own? Then feel free to ask us using the button below. You decide whether your question may be published.

Advantages

With the Cover-1 system, book cover production is possible completely without set-up times. All data is transmitted to the system via a barcode system and the machine adjusts to the next cover to be processed. The Cover-1 system is very easy to operate via an integrated touch screen, which also allows data to be transferred to the machine manually. Cover material and boards are automatically cut to size and the viscosity of the glue is continuously checked. The operator can thus fully concentrate on the manual parts of the process: Gluing the cover material, placing the trimmed boards and triggering the case-making process.

The Cover-1 system enables completely on-demand hardcover production.

A simple training of the staff is sufficient to operate the Cover-1 system.

All necessary pre-configuration can be made conveniently via the touch screen.

With the PräziTrim, cardboard is cut to size fully automatically and accurately.

The PräziCoat Pro gluing machine has automatic glue and viscosity control.

The case is produced in the PräziCase Pro, incl. in-line corner cutting.

The PräziSheet automatically cuts printed and/or laminated cover material to final size.

The PräziSpine enables the production of cases for books with round spines.

The Cover-1 system enables completely on-demand hardcover production.

A simple training of the staff is sufficient to operate the Cover-1 system.

All necessary pre-configuration can be made conveniently via the touch screen.

With the PräziTrim, cardboard is cut to size fully automatically and accurately.

The PräziCoat Pro gluing machine has automatic glue and viscosity control.

The case is produced in the PräziCase Pro, incl. in-line corner cutting.

The PräziSheet automatically cuts printed and/or laminated cover material to final size.

The PräziSpine enables the production of cases for books with round spines.

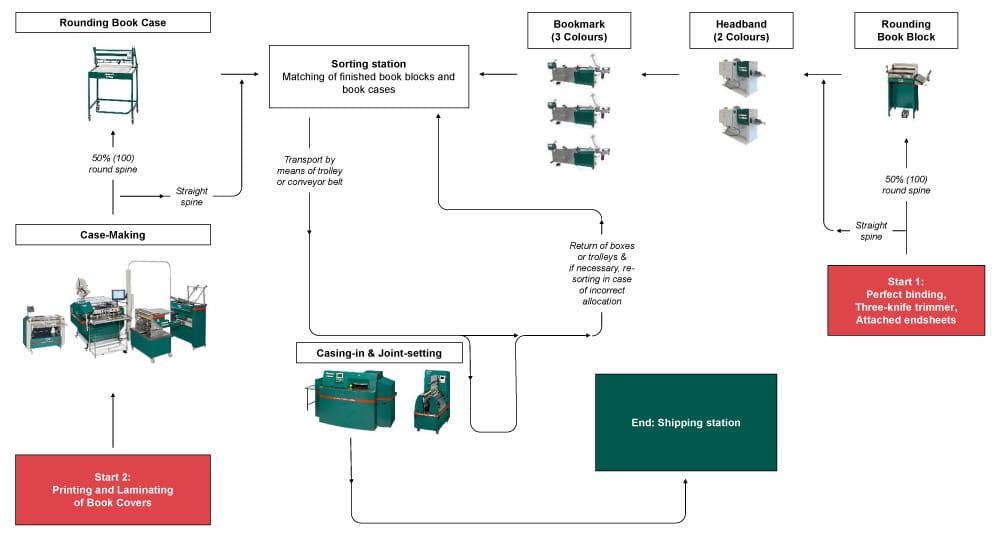

Books-on-Demand Workflow

Our scalable on-demand workflow minimises sorting effort and downtime risk (machines are designed to meet on-demand production requirements and are stand-alone; in case of problems on one machine, production can continue on the remaining machines). This example workflow takes into account the following complexity of books: 50% books with round spine, 100% books with capital band (2 colours), 100% of books with bookmark band (3 colours). Stations that are not required (e.g. rounding, capital band, bookmark) can simply be omitted.

Individually available components of the system

With the exception of the PräziSpine soft spine cutter, all machines from the Cover 1 system are also available individually: