PräMelt OT24 Digital - hotmelt jelly

for laminated covers, semi-automatic production

€10.65 *

In stock, deliverable at short notice

€10.65*

€9.65*

€8.88*

€8.13*

19% VAT:

PräMelt OT24 Digital is an animal jelly for book cover production with medium open time and sets quickly immediately.

- Container size: PE bag with 2.5 kg

- Suitable for case-making

- Average open time

- Rapidly sets immediately

- Processing temperature approx. 60 °C

- Refractometer value 61-65 %

OT24 Digital is particularly suitable for the processing of digitally printed covers and semi-automatic production such as our gluing machine type PräziCoat in connection with our case-making machines type PräziCase or PräDeka XL.

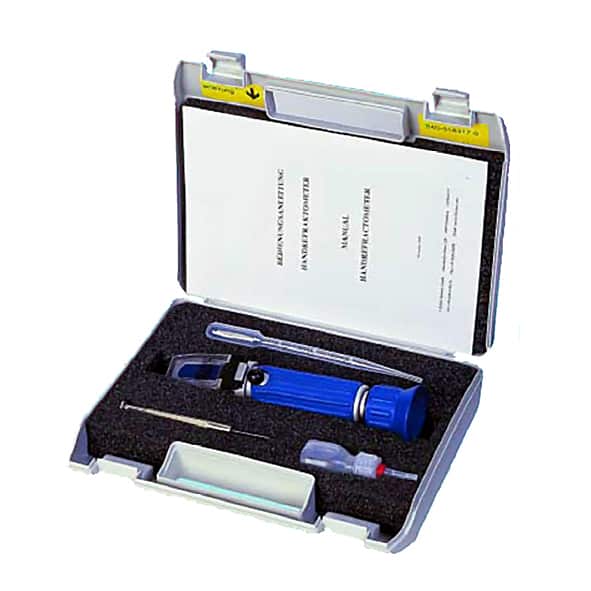

To determine and check the correct viscosity (solids content) of the adhesive, we recommend our refractometer with art. no. 6703-062.

To measure and check the glue temperature, we recommend our infrared thermometer with art. no. 67041002.

Processing hotmelt jelly

To ensure reliable production when processing hotmelt jelly, processing temperature and refractometer value (solids content) are crucial. As hotmelt jelly is heated and loses water in the process, the solids content is not constant and changes depending on temperature, environmental variables and water supply during production. Thus, for optimum tack, water must be added during operation. This can be done either manually by the operator or automatically with our automatic water supply for gluing machines PräVis or completely automated in a gluing machine with viscosity control such as the PräziCoat Pro.

Processing temperature

Hotmelt jellies are processed at a temperature of 60 +/- 5°C (measured in the glue basin). At this temperature the jelly is liquid. Heating above 70°C permanently must be avoided so that the adhesive / proteins do not burn and the jelly loses its adhesive strength. When the adhesive is applied, the transition from the liquid sol phase to the solid gel phase takes place at the so-called gelling point. In this process, the jelly develops an immediate strong adhesive force, the 'tack'.

Water content / refractometer value

Depending on the type of binding material, the adhesives need to be diluted with more or less water: light, flexible cloth with a higher water content, 'bulky' papers and heavy cover material with a lower water content. In the beginning, between 5 % and 10 % warm water should be added. These are estimates. The dilution ratio depends on the materials used and the ambient temperature / humidity. If the dilution is insufficient and / or the temperature is too low, the adhesive will pull thread.

For example, the refractometer value for cellophane-coated papers should be approx. 55-60%. If the 'water content' is too high, the open time is too long and the 'tack' is reduced. If the water content is too low, the opposite can occur with corresponding disadvantages. The refractometer value can be checked with a so-called refractometer. Here, some liquid jelly is taken from the glue basin or from the roller and applied to the mirror window of the refractometer. In the refractometer, which is now held against the light, there is a scale which now shows the corresponding value. If the refractometer value does not correspond to the recommended value, perfect case-making cannot be guaranteed.

Cleaning

The machines (usually glue rollers and glue basins) can be cleaned with warm water. When the machine is used again the next day, the glue can usually remain in the glue basin, but must then of course be reheated and supplied with water before the next production run. For persistent soiling and other parts, except glue roller and glue basin, we recommend the use of our separating and cleaning agent Partinol.

Our recommendation

We recommend the product PräMelt OT24 for digitally printed covers and PräMelt OT30 for all materials (not specifically printed, laminated covers) for semi-automatic production of book covers and Plakal 371 for fully automatic production. For use on fast-running laminators, we recommend Plakal Covertack 531; for manual work and slow-running laminators, we recommend Plakal Covertack 535. And if you've tried everything or want to play it safe, we recommend Plakal Covertack 544V, our recommendation for particularly difficult surfaces in semi-automatic production.

| Dimensions | |

| Contents: | PE bag / 2.5 kgs |

|---|---|

| Colour | |

| Colour: | yellowish-transparent |

| Adhesive properties | |

| Adhesion: | very strong |

| Adhesive: | Protein glue |

| Adhesive application: | Gluing machine (Heated), Laminating line |

| Open time: | medium |

| Stickiness: | elastic, quick tacking |

| Viscosity (in mPas): | 1000 - 1200 |

| Technical details | |

| Refractometer value (undiluted): | 61 - 65 % |

| Type: | Hotmelt jelly |

| Usage: | Book cover production with digitally printed covers, genuine photo papers and other difficult surfaces. |

| Working temperature (in ° C): | 61 - 63 |

| Other properties | |

| Category: | Hotmelt jelly |

| Ecological features: | biodegradable |

| Minimum order quantity: | as of 1 PE bag of 2.5 kgs |

| Recommendation: | For semi-automatic production of digitally printed, laminated covers |

| Sales unit: | Box of 20 kgs (8 PE bags of 2,5 kgs) |

| Usage: | Book cover production with digitally printed covers, genuine photo papers and other difficult surfaces. |

Login

Below you can see questions that other customers have asked about this product. Do you have a question of your own? Then feel free to ask us using the button below. You decide whether your question may be published.

Ist Gallerte frostempfindlich (Versand, Lagerung)?

Gallerte ist nicht frostempfindlich, sie kann sogar eingefroren werden. Sie darf aber nicht zu kalt im Warmleimbecken erwärmt werden, sondern sollte bei Verwendung Zimmertemperatur haben, da es ansonsten zu Schaumbildung kommt.

Liebe Grüße

Product comparison: Hotmelt Jelly

We compare the different hotmelt jellies from our product portfolio below to give you a better overview of the differences between the individual products. Should you require further assistance or individual advice, please feel free to contact us.